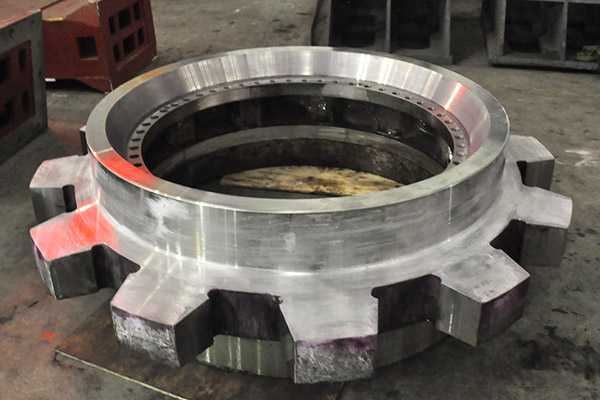

Track Shoe Sprockets

Applicable devices: creeper tread

Application: cement, non-metal mines etc.

Customizable or not: Yes

Product introduction

Sprocket sometimes is calling sprocket gear or chain wheel. It’s usually as a drive wheel capable of huge driving force even if in heavy machineries by roller chain or by crawler belt. Most of sprocket requiring very high HV hardness of tooth surface more than 1000, almost surface hardened by plasma nitriding.

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart