Renewable Design for Transfer Ladle In Smelting Workshop - Riding wheel for rotary kiln – Special Metal Detail:

Riding wheel for rotary kiln

Weight:7~42T

Applicable device: Rotary Kilns

Application: Cement, metallurgy, chemical, construction industries, etc

Customizable: Yes

Product introduction

Our main material for the Riding wheel for rotary kiln is similar to followings:

|

Standard Specifications for Cast Steel ZG55 |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS3100 | A5 |

| USA | AISI/SAE | UNS J05000 |

| Germany | / | / |

| Japan | / | / |

| International | ISO 3755:1991 | 340-550 |

|

Standard Specifications for Cast Steel ZG42CrMo |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS 970-1 | 708A42 |

| USA | ASTM A29/A29M | 4140/4142 |

| Germany | EN10083-1 | 42CrMo4 |

| Japan | JIS G4053-2003 | SCM440 |

| International | ISO 683/1 | 3 |

Advantages:

1. Large load bearing, good continuous operation performance

We CSM riding wheel are made from ZG55 and ZG42CrMo. This kind of material guarantee the quality of riding wheel, and also make riding wheel large loading bearing and good continuous operation performance.

2. Simple structure, convenient to adjust and maintain.

This kind of riding wheel uses rolling bearing wheel sets, and is simple in structure and convenient to maintain.

3. Heat treated through normalizing and tempering, hardness of riding wheel is higher.

We CSM apply normalizing and tempering heat, which makes riding wheel’s outer surface hardness higher than 200HB; guarantee the quality of riding wheel for rotary kiln.

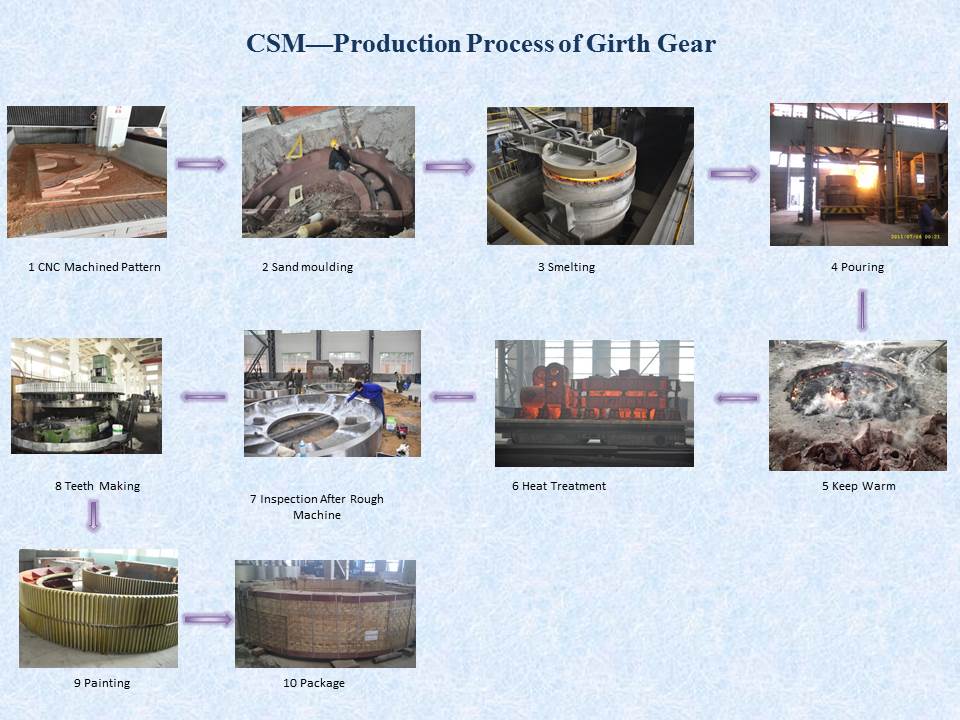

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

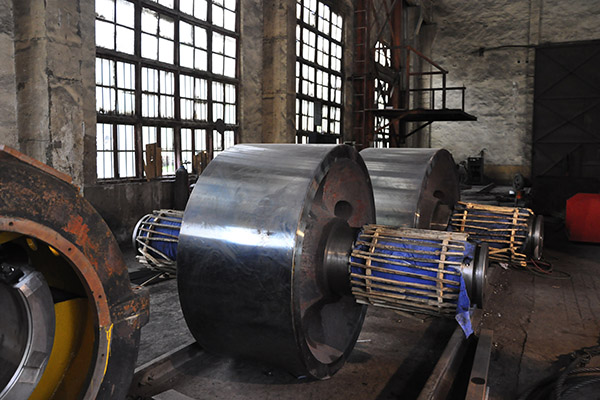

Picture:

Product detail pictures:

Related Product Guide:

Worst insults and racial slurs against the Irish | Copper Foil Manufacturing Facilities

75 Best Gifts for Daughters: The Ultimate List (2018) | Cast Steel Nodes

Attaining consumer satisfaction is our firm's purpose for good. We'll make wonderful efforts to produce new and top-quality merchandise, meet up with your special necessities and supply you with pre-sale, on-sale and after-sale products and services for Renewable Design for Transfer Ladle In Smelting Workshop - Riding wheel for rotary kiln – Special Metal, The product will supply to all over the world, such as: Italy , Costa rica , Estonia , We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!