OEM/ODM Factory Mitsubishi L200 Con Rod Bearing - Ball Mill End Cover, Stationary Inlet and Outlet – Special Metal Detail:

Ball mill head

Shanghai Special Metal Co., Ltd supplies ball mill head. The materials of mill head are normally selected low carbon steel and low alloy steel. It’s produced by casting, used in ball grinding mill, including the feed end and outlet end, our head/cap for the bellow ball grinding mill.

Ball mill data:

| Model(mmxmm) | Speed of bucket(r/min) | Weight of ball(t) | Size of feed opening(mm) | Production(t/h) | Power(kw) |

| φ900×1800 | 38 | 1.5 | ≤20 | 0.65-2 | 18.5 |

| φ1200×2400 | 32 | 3.8 | ≤25 | 1.5-4.8 | 45 |

| φ1500×5700 | 27 | 15 | ≤25 | 3.5-6 | 132 |

| φ2200×5500 | 21 | 30 | ≤25 | 10-22 | 370 |

| φ2400×10000 | 20.8 | 49 | ≤25 | 22 | 630 |

| φ3000×13000 | 18.2 | 115 | ≤25 | 40-42 |

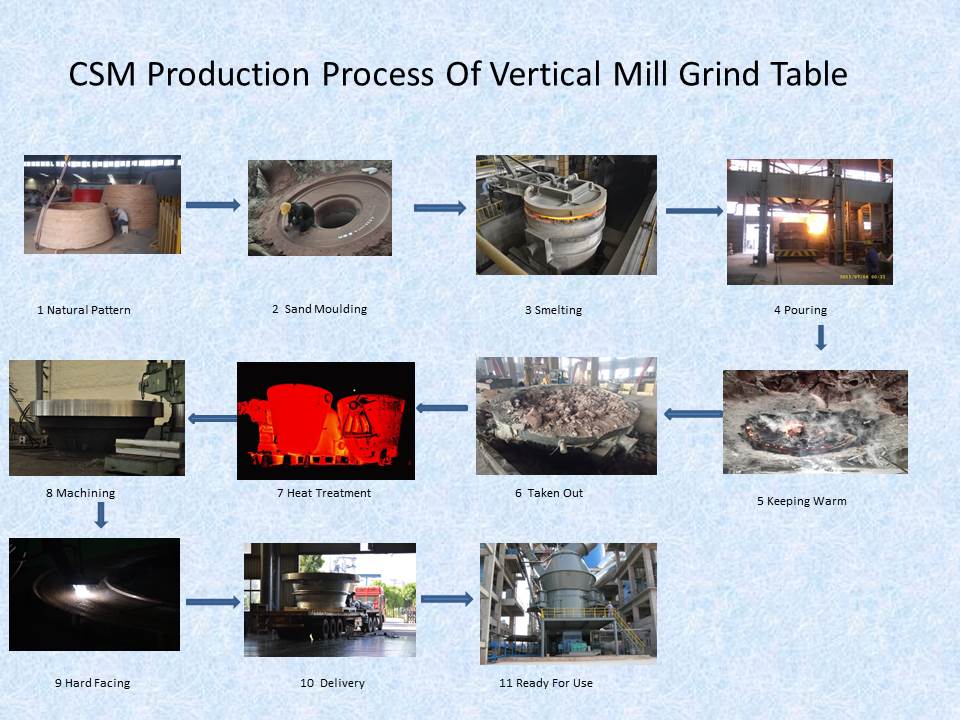

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

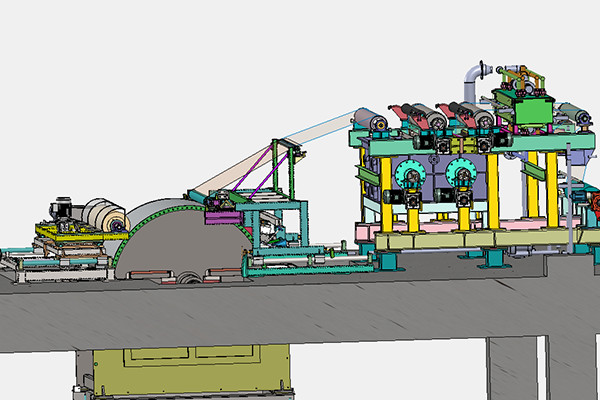

Product detail pictures:

Related Product Guide:

Dow hits record close, but Facebook weighs on S&P | Single Stage Hammer Crushers

In Photos: Anglo-Saxon Island Settlement Discovered Live Science Live Science | Slag Pots

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for OEM/ODM Factory Mitsubishi L200 Con Rod Bearing - Ball Mill End Cover, Stationary Inlet and Outlet – Special Metal, The product will supply to all over the world, such as: Latvia , Bogota , Rwanda , Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!