Factory Price Cgm-1000 Roller Mill - Vertical Mill and Spare Parts vertical mill Grinding roller – Special Metal Detail:

Grinding roller for vertical mill

Weight: 20-120T

Applicable devices: vertical mills, mineral slag vertical mills, cement vertical mills, steel slag vertical mills, nickel slag mills, raw material vertical mills and coal vertical mills.

Application: Cement, building material, chemical, coal and others

Customizable: Yes

Product introduction

Grinding roller is a core part of vertical mill. Shanghai Special Metal Co., Ltd supplies customized service according to customers’ requirements. Besides, Shanghai Special Metal Co., Ltd obtains good reputations on grinding roller casting, finish machining and bead welding service.

Our main material for the Grinding roller for vertical mill is similar to followings:

|

Standard Specifications for Cast Steel ZG30Mn |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS 970 | 080A30/080M30 |

| USA | ASTM A29M | 1030 |

| Germany | DIN EN 10083-2 | 30Mn5 |

| Japan | JISG4051-79 | S30C |

Advantage

1. High hardness, anti-cracking and wear resistant

2. Arc air gouging technology is applied by SHANGHAI SPECIAL METAL CO., LTD during finishing, making sure steel castings good appearance quality.

3. SHANGHAI SPECIAL METAL CO., LTD promise: will do inspections before delivery to make sure each produced grinding roller is qualified, and refuse any inferior and defective products to be delivered.

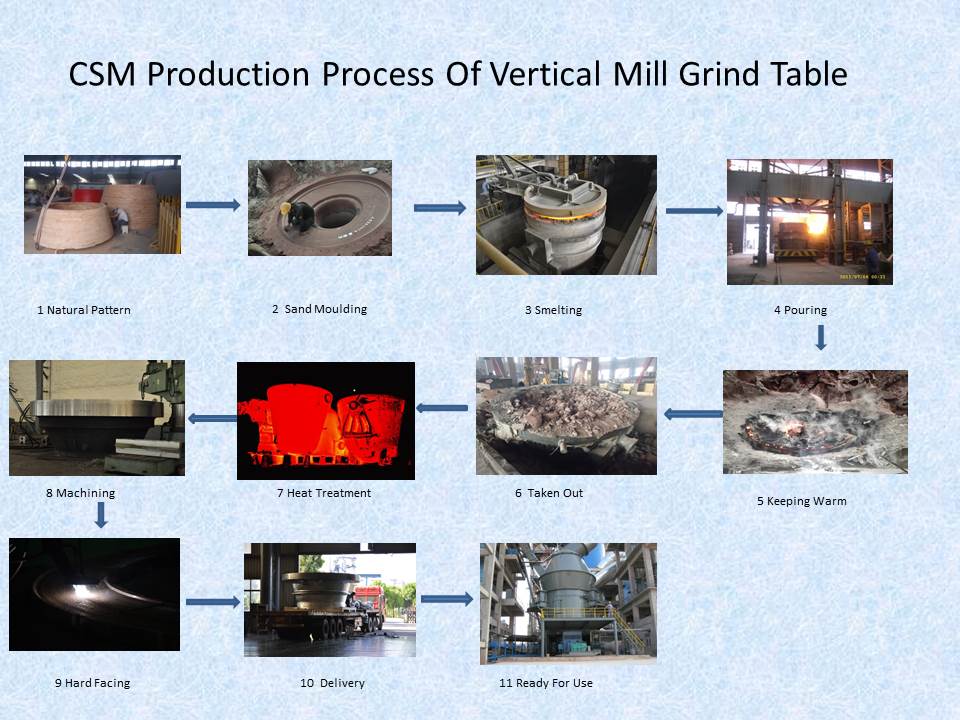

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Pictures:

Product detail pictures:

Related Product Guide:

Platform31 kennis- en netwerkorganisatie voor stad en regio | Lead Ingot Mold

Global Atomizing Copper Powder Market 2019: Pometon, Fukuda Metal Foil & Powder, Kymera International | Cast Steel Nodes

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for Factory Price Cgm-1000 Roller Mill - Vertical Mill and Spare Parts vertical mill Grinding roller – Special Metal, The product will supply to all over the world, such as: Roman , Algeria , Malta , We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.