Trending Products Rotary Melting Furnace - Mechanical Machine Pump Spares Water Pump Casing – Special Metal Detail:

The pump casing we offer can meet the followings:

1. Tolerance size of the casting shall conform to ISO8026-3 DCTG 13-RMA 6(RMAG H)-GCTG 7-DS

2. Cracks, burnt, sand and slag inclusions are not allowed. On the unhandled surfaces should not be defects reducing the strength, performance and degrade casting presentation. Allowed correction of welding, in which defective cutting may be performed by the manufacturer’s instruction. Locations of these defects in the casting and the butchering size under welding must be registered and entered in the casting documents. After removal of butchering defects, the surface should be grinded and monitored for completeness remove defects by dye penetration

3. Carry out UT of the castings: the end surfaces along the entire length in the area of the flange connector of the pump housing and cover (zone 1) in the area of the suction flange connector (zone2),in the area of the discharge flange connector (zone3), permitted without correcting defects of the equivalent size to 5mm not more than 3pcs.

4. The conformity checking with the chemical composition of the steels should be carried out from the each melt.

The chemical composition of castings:

|

Mass fraction of component % |

||||

|

C |

Mn |

Si |

P | S |

|

No more than |

||||

| 0.22-0.30 | 0.45-0.9 | 0.2-0.52 | 0.05 | 0.05 |

5. The steel mechanical properties: Tensile strength not less 441MPa, elongation Q not less 19%, impact strength not less 392KJ/m2, hardness HB 121-151. The mechanical properties of the steel are necessary to control for each melt. Test results apply to all the castings from this melt, heat-treated in the same mode, record by automatic devices.

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

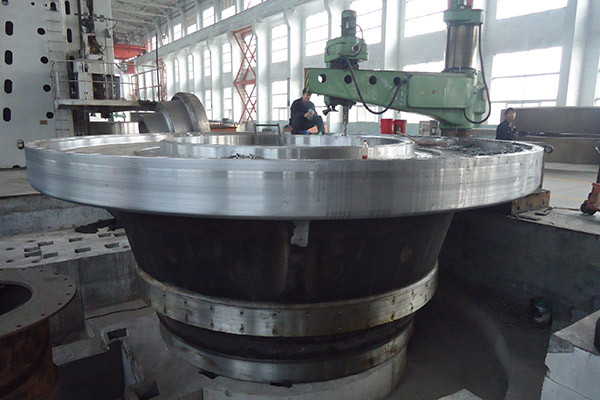

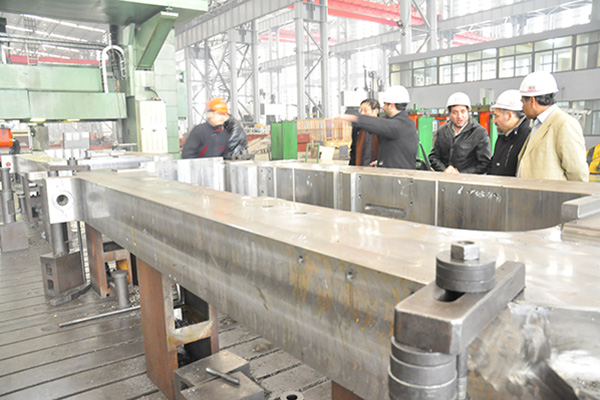

Product detail pictures:

Related Product Guide:

Black Desert Online Fishing Guide | Cast Steel Nodes

China’s environmental crackdown means big business for Japan - Nikkei Asian Review Arrow Artboard Artboard Title Chevron Cross Eye Icon Icon Facebook Icon Linkedin Shape Icon Mail Contact Path Layer Icon Mail Menu Burger Positive Arro | Lead Ingot Mold

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for Trending Products Rotary Melting Furnace - Mechanical Machine Pump Spares Water Pump Casing – Special Metal, The product will supply to all over the world, such as: Oman , Ireland , Swiss , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!