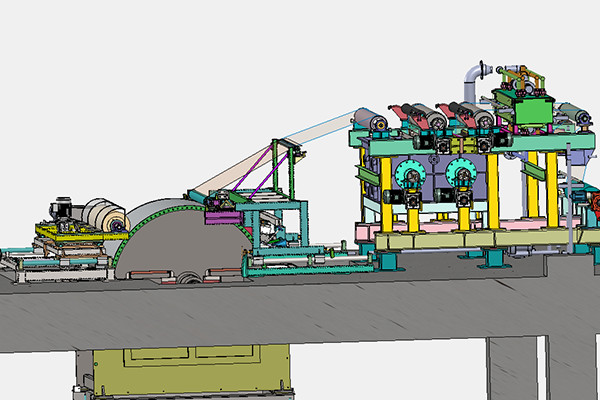

Special Design for Stand Desk Integrated Motor And Ball Screw - Chain grating machine Grate Plate – Special Metal Detail:

Product Introduction

The grate castings cycle through the grate furnace on a continuous cycle and carry the magnetite iron ore pellets through the process and into the kiln.

Processing Steps:

· In the first section of the grate furnace (drying) the temperatures are fairly low (around 200C to 240C),

· In the second section of the furnace (dehydration) the temperature are higher (around 480C to 520C),

· In the third section of the furnace (pre-heat 1) the process temperature rises (980C to 1020C),

· n the final section of the furnace (pre-heat 2) the process temperature reaches its maximum (1050C to 1100C)

· After the preheat 2 section the grate castings discharge their pellets into the kiln and then run along the return side of the grate in ambient air where they cool down before getting loaded with pellets again and entering the furnace for the next cycle.

The temperatures above are the process gas temperatures that the castings are exposed to. The castings themselves would not quite reach these temperatures and would be slightly cooler.

The thermal cycling of the grate castings is continuous as it cycles through the grate during production.

The maximum temperature of the casting goes to approximately 650C when it discharges its load into the kiln and then the castings cool down to approximately 150C in free air, as it returns to the tail end.

Shanghai Special Metal Co., Ltd supplies very high wear grates for mining environments to maximize its life.

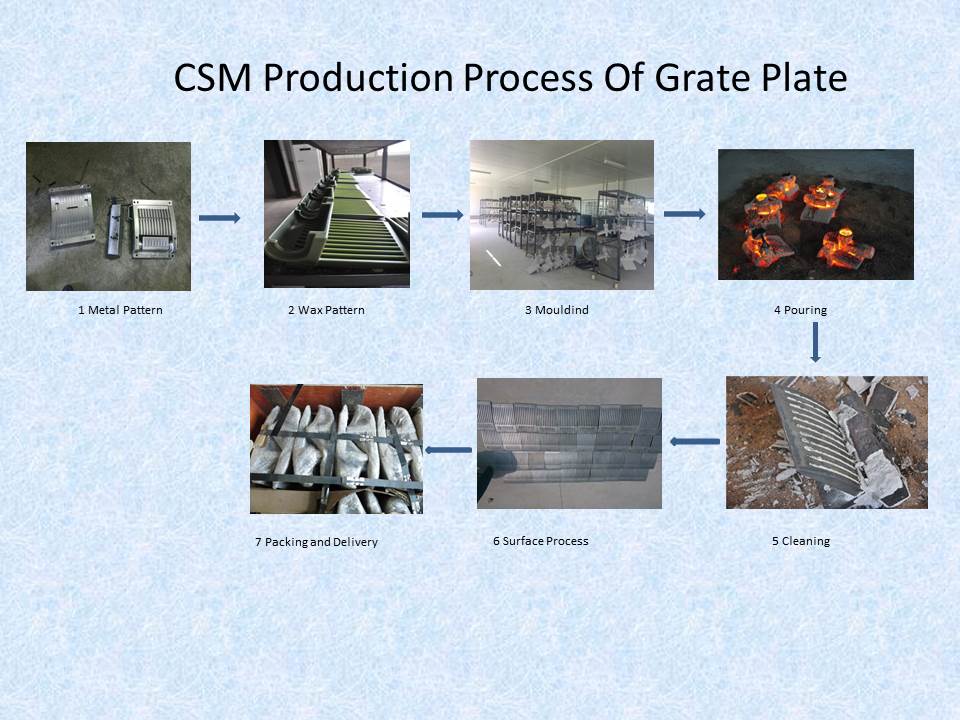

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

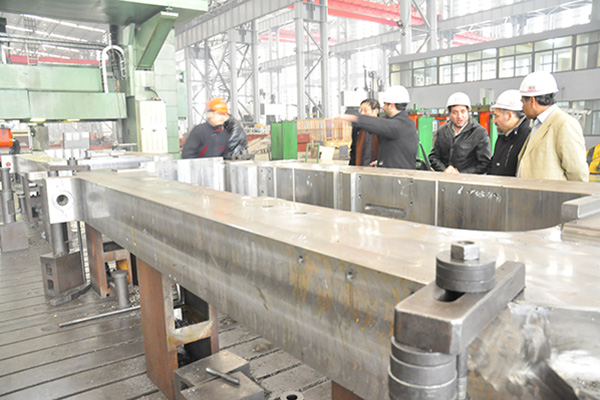

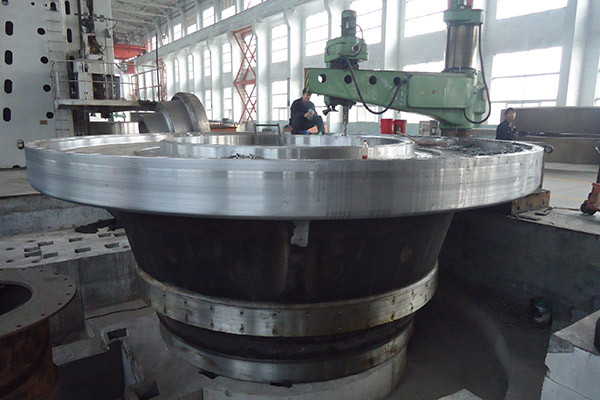

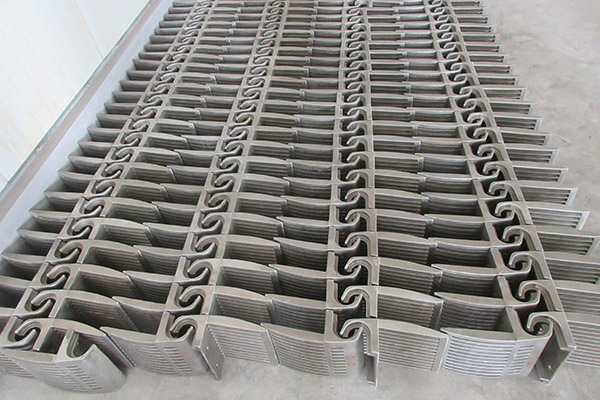

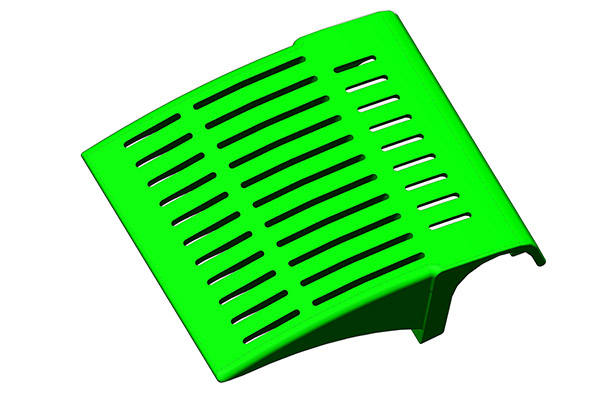

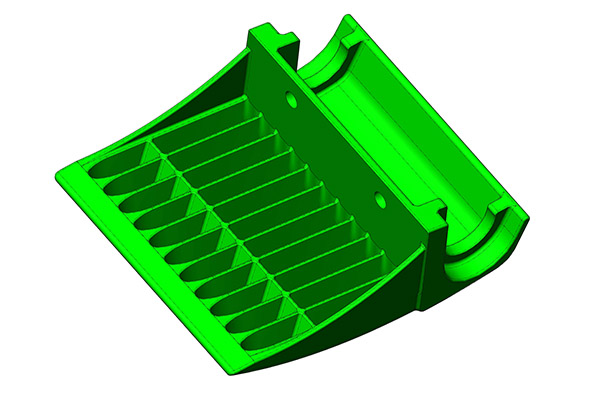

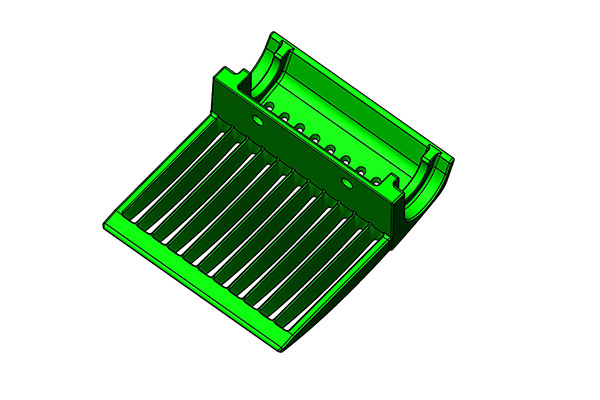

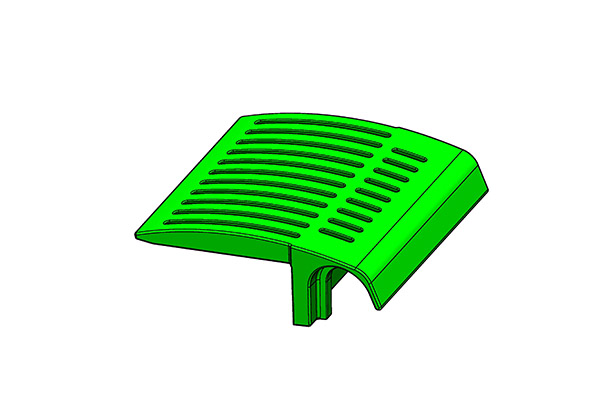

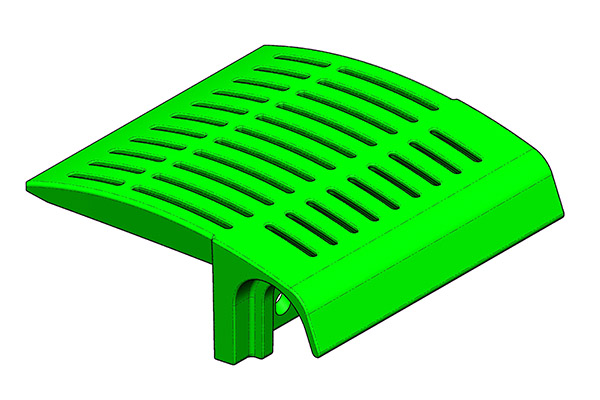

pictures:

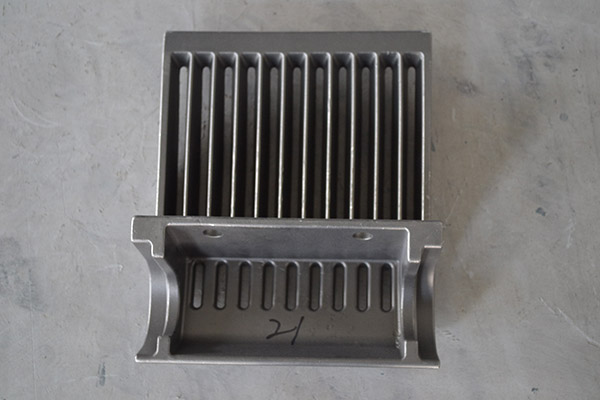

Product detail pictures:

Related Product Guide:

Evertiq | Slag Pots

Power Integrity by Example eBook Available for Download | Cast Steel Nodes

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Special Design for Stand Desk Integrated Motor And Ball Screw - Chain grating machine Grate Plate – Special Metal, The product will supply to all over the world, such as: Australia , Uganda , Niger , "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.