Personlized Products Feed Mill Equipment - Transfer Ladle in Smelting Workshop Crucible – Special Metal Detail:

Introduction

Crucibles are cast steel molds for the casting of aluminum ingot for remelt storage and/ or transportation. Dimensions and design can be customized to customer requirements, including the casting of customer’s logo, and additional of feet and/or lugs for material handling.

INDUSTRIES : Cast houses; Remelter

APPLICATIONS : Cast ingot Solid storage/ transportation Empty trough / furnace

MATERIAL AVAILABLE : QT450-12/ASTM A536/65-45-12

Shanghai Special Metal Co., Ltd is a comprehensive and professional supporting supplier in industrial field which owns great production capacity, advanced management ability, splendid procedure control system and first rate service so that we can provide high quality products as well as service to the worldwide customers.

In principle there are three sorts of materials available for the manufacture of crucibles: Grey Cast Iron, Spheroidal Graphite (S.G.) Iron and Cast Steel.

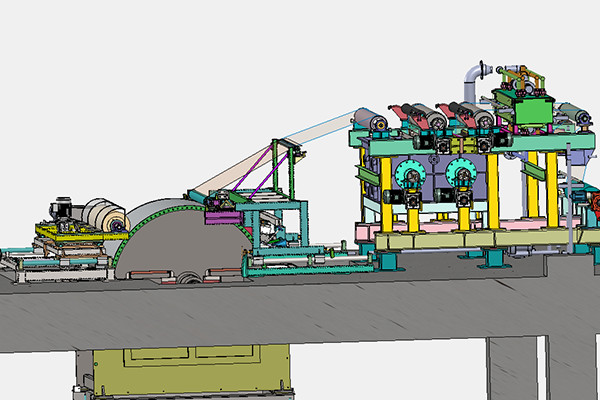

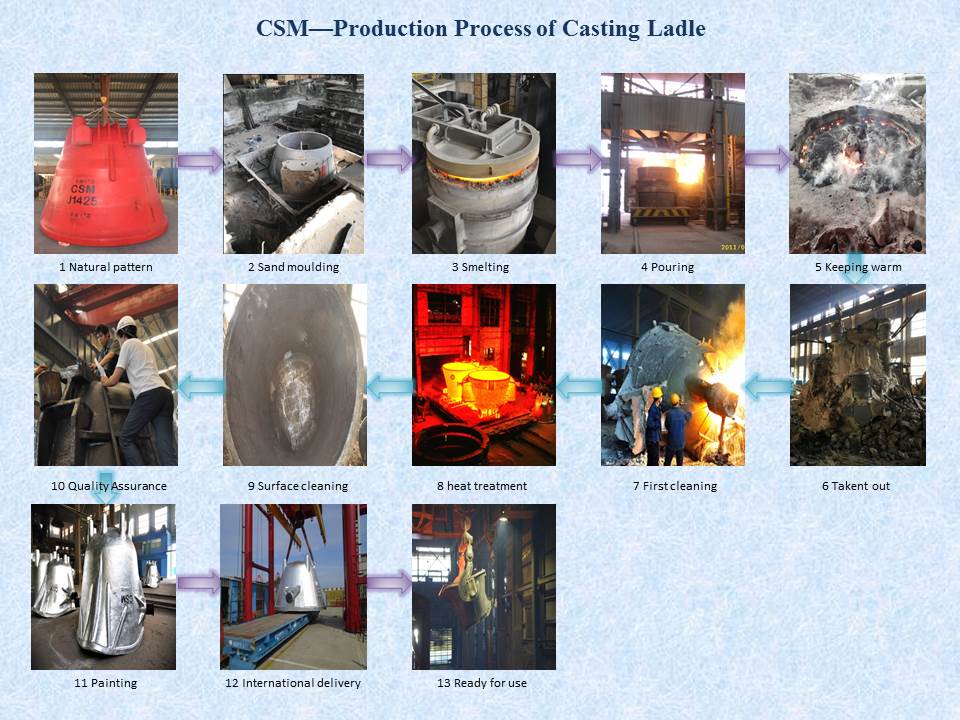

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

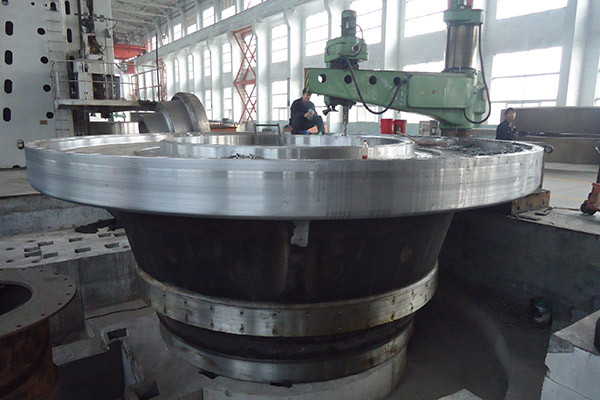

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

Pictures:

Product detail pictures:

Related Product Guide:

Copper Foil for Wireless charging Market Latest Technology, Outlook, Trend and Growth Forcast by Key Players: CCP, NPC, Co-Tech | Copper Foil Manufacturing Facilities

Arup Develops Affordable 3D-Printing Sand Casts for Complex Steel Structural Elements | Lead Ingot Mold

To get the stage of realizing dreams of our employees! To build a happier, more united and much more skilled crew! To reach a mutual benefit of our prospects, suppliers, the society and ourselves for Personlized Products Feed Mill Equipment - Transfer Ladle in Smelting Workshop Crucible – Special Metal, The product will supply to all over the world, such as: British , Malaysia , Slovenia , We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.