Original Factory Phosphate Ore Grinding Mill Equipment - Girth gear for rotary kiln, ball mill and tube mill – Special Metal Detail:

Gear ring

Weight: 10~35T

Applicable devices: rotary kiln, ball mill, tube mill

Application: Cement, building material, metallurgy etc.

Customizable or not: Yes

Product introduction

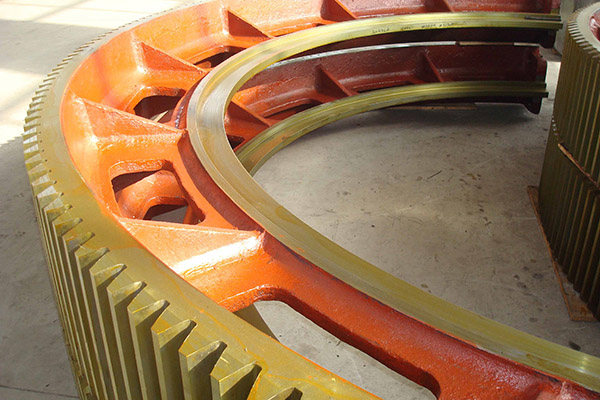

Gear ring is the main part of rotary kiln and ball mill which has to run for a long time, therefore, there is high quality requirement for gear ring in production.

Our main material for the Gear ring is similar to followings:

|

Standard Specifications for Cast Steel |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS EN 10083/2-1991 | C45 |

| USA | ASTM A 29/A29M-04 | 1045 |

| Germany | DIN EN 10083-2-2006 | C45/CK45 |

| Japan | JIS G5111 | SCC5 |

| International | ISO 683/1 | C45/C45E4/C45M2 |

|

Standard Specifications for Cast Steel |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS 970-1 | 708 M40 |

| USA | ASTM A 29/A29M-04 | 4140/4142 |

| Germany | DIN EN 10083-1-1996 | 42CrMo4 |

| Japan | JIS G4053-2003 | SCM440 |

| International | ISO 683/1 | 3 |

Heavy Load Transmission Gear Ring Hardness Comparison

|

Type |

Treatment |

Hardness |

||

|

Pinion |

Gear |

Pinion |

Gear |

|

|

Spur Gear

|

Quenching & Tempering

|

Normalizing |

240~270HB |

180~220HB |

|

Quenching & Tempering |

260~290HB |

220~240HB |

||

|

Quenching & Tempering |

280~310HB |

240~260HB |

||

|

Quenching & Tempering |

300~330HB |

260~280HB |

||

|

Helical Gear |

Quenching & Tempering |

Normalizing |

240~270HB |

160~190HB |

|

Normalizing |

260~290HB |

180~210HB |

||

|

Quenching & Tempering |

270~300HB |

200~230HB |

||

|

Quenching & Tempering |

300~330HB |

230~260HB |

||

Advantage

Shanghai Special Metal Co., Ltd adopts unique heat treatment to optimize the gear ring structure, to enhance hardness、wear resistance and impact force.

Shanghai Special Metal Co., Ltd uses high strength steel to cast gear ring and optimize rotary kiln to ensure the stability under long working time and prolongs service time.

Shanghai Special Metal Co., Ltd has a strong ability of producing steel casting and we can do mass production of gear ring in short cycle with large amount.

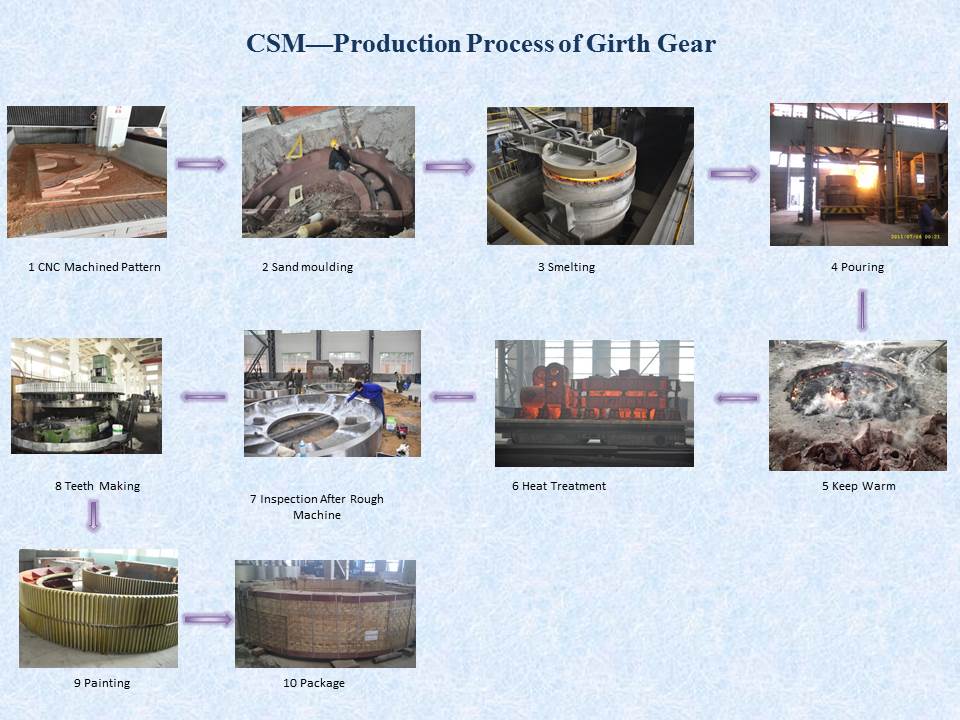

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Pictures:

Product detail pictures:

Related Product Guide:

‘Kidney twins’ celebrating first holiday season after life-saving donation | Northwest Indiana Business Headlines | Copper Foil Manufacturing Facilities

MIT may have just solved how to mass-produce graphene | Copper Foil Manufacturing Facilities

We know that we only thrive if we can guarantee our combined rate competiveness and good quality advantageous at the same time for Original Factory Phosphate Ore Grinding Mill Equipment - Girth gear for rotary kiln, ball mill and tube mill – Special Metal, The product will supply to all over the world, such as: luzern , Lithuania , Comoros , We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!