OEM Supply Energy Saving Rotary Kiln - Ball Mill Hollow Shaft – Special Metal Detail:

Ball mill hollow shaft

Weight: 5-30T

Applicable device: ball mil, cement machinery

Application: Cement, metallurgy, building material and others

Customizable: Yes

Introduction

Hollow shaft is an important part of ball mill. Its function is bearing the rotary of ball mill shell. Technically, hollow shafts should not have below holes and sand holes on the neck of spherical tile and circular arc neck of shell connection. When producing, spherical tile needs grinding after part machining, to secure precision and smooth finish. This requires very high standard of casting technology. And SHANGHAI SPECIAL METAL CO., LTD is one of foundries who can produce high quality hollow shafts.

Our main material for the Ball mill hollow shaft is similar to the followings:

|

Standard Specifications for Cast Steel ZG230-450 |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS 3146-1 | CLA1Gr.B |

| USA | AISI/SAE | UNS J03003 |

| Germany | DIN 1681 | GS-52 |

| Japan | JIS-G5101 | SC410 |

| International | ISO3755 | 230-450 |

Advantage

1. SHANGHAI SPECIAL METAL CO., LTD applies unique heat treatment technology, has improved the hardness and impact resistance of hollow shaft.

2. SHANGHAI SPECIAL METAL CO., LTD uses high strength steel to produce hollow shaft. In early stage of casting, SHANGHAI SPECIAL METAL CO., LTD engineers optimized hollow shaft’s technological structure according to operation features of ball mill. This optimization largely secures hollow shaft’s stability and working life under long-time running.

3. SHANGHAI SPECIAL METAL CO., LTD has strong manufacturing capacities of steel castings. We are able to abundantly produce parts like hollow shaft within a short period.

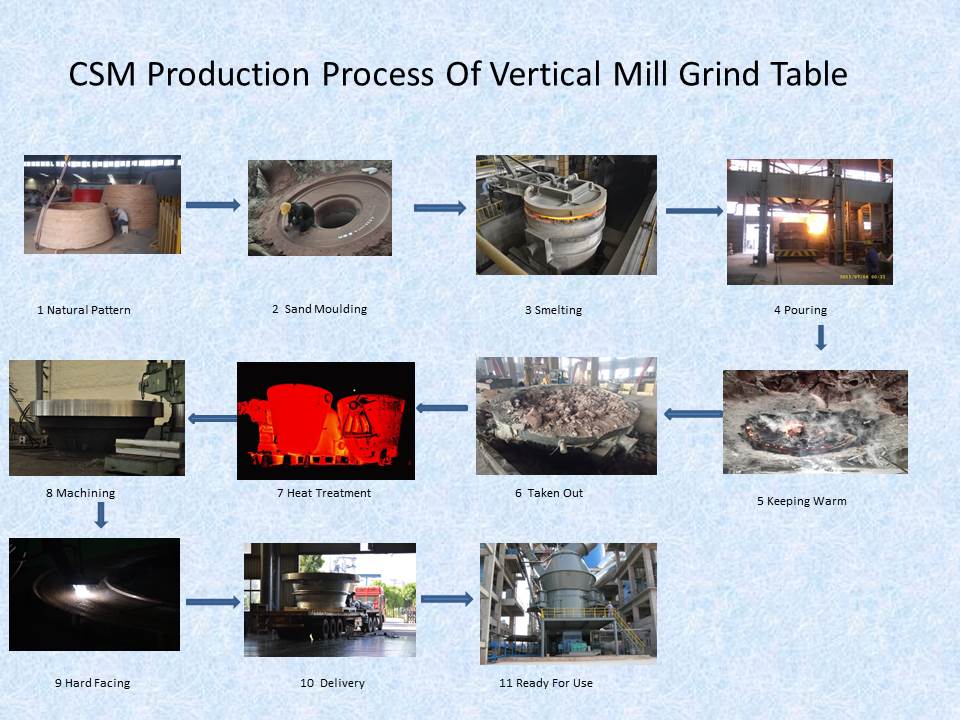

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Pictures:

Product detail pictures:

Related Product Guide:

AT&T Ignores Numerous Pitfalls, Begins Kicking Pirates Off Of The Internet | Cast Steel Nodes

Shobak Castle’s commercial role in mediaeval time uncovered | Copper Foil Manufacturing Facilities

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for OEM Supply Energy Saving Rotary Kiln - Ball Mill Hollow Shaft – Special Metal, The product will supply to all over the world, such as: Florida , Madras , Cape Town , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!