OEM Factory for Casted Slag Pot - Mechanical Machine Pump Spares Water Pump Casing – Special Metal Detail:

The pump casing we offer can meet the followings:

1. Tolerance size of the casting shall conform to ISO8026-3 DCTG 13-RMA 6(RMAG H)-GCTG 7-DS

2. Cracks, burnt, sand and slag inclusions are not allowed. On the unhandled surfaces should not be defects reducing the strength, performance and degrade casting presentation. Allowed correction of welding, in which defective cutting may be performed by the manufacturer’s instruction. Locations of these defects in the casting and the butchering size under welding must be registered and entered in the casting documents. After removal of butchering defects, the surface should be grinded and monitored for completeness remove defects by dye penetration

3. Carry out UT of the castings: the end surfaces along the entire length in the area of the flange connector of the pump housing and cover (zone 1) in the area of the suction flange connector (zone2),in the area of the discharge flange connector (zone3), permitted without correcting defects of the equivalent size to 5mm not more than 3pcs.

4. The conformity checking with the chemical composition of the steels should be carried out from the each melt.

The chemical composition of castings:

|

Mass fraction of component % |

||||

|

C |

Mn |

Si |

P | S |

|

No more than |

||||

| 0.22-0.30 | 0.45-0.9 | 0.2-0.52 | 0.05 | 0.05 |

5. The steel mechanical properties: Tensile strength not less 441MPa, elongation Q not less 19%, impact strength not less 392KJ/m2, hardness HB 121-151. The mechanical properties of the steel are necessary to control for each melt. Test results apply to all the castings from this melt, heat-treated in the same mode, record by automatic devices.

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

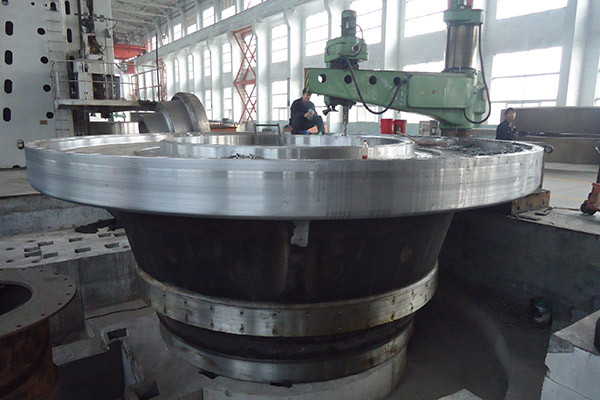

Product detail pictures:

Related Product Guide:

Global Copper Foil Shielding Tape Market 2018 (Sales & Key Players) – 3M, Alpha Wire, Tapes Master, Shielding Solutions, Nitto, Hilltop Products, Hilltop Products | Copper Foil Manufacturing Facilities

Wireless load monitors on song at Royal College of Music | Single Stage Hammer Crushers

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for OEM Factory for Casted Slag Pot - Mechanical Machine Pump Spares Water Pump Casing – Special Metal, The product will supply to all over the world, such as: Guyana , Georgia , Munich , You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.