Manufacturing Companies for 1000kg Copper Scrap Smelting Furnace - Ball Mill End Cover, Stationary Inlet and Outlet – Special Metal Detail:

Ball mill head

Shanghai Special Metal Co., Ltd supplies ball mill head. The materials of mill head are normally selected low carbon steel and low alloy steel. It’s produced by casting, used in ball grinding mill, including the feed end and outlet end, our head/cap for the bellow ball grinding mill.

Ball mill data:

| Model(mmxmm) | Speed of bucket(r/min) | Weight of ball(t) | Size of feed opening(mm) | Production(t/h) | Power(kw) |

| φ900×1800 | 38 | 1.5 | ≤20 | 0.65-2 | 18.5 |

| φ1200×2400 | 32 | 3.8 | ≤25 | 1.5-4.8 | 45 |

| φ1500×5700 | 27 | 15 | ≤25 | 3.5-6 | 132 |

| φ2200×5500 | 21 | 30 | ≤25 | 10-22 | 370 |

| φ2400×10000 | 20.8 | 49 | ≤25 | 22 | 630 |

| φ3000×13000 | 18.2 | 115 | ≤25 | 40-42 |

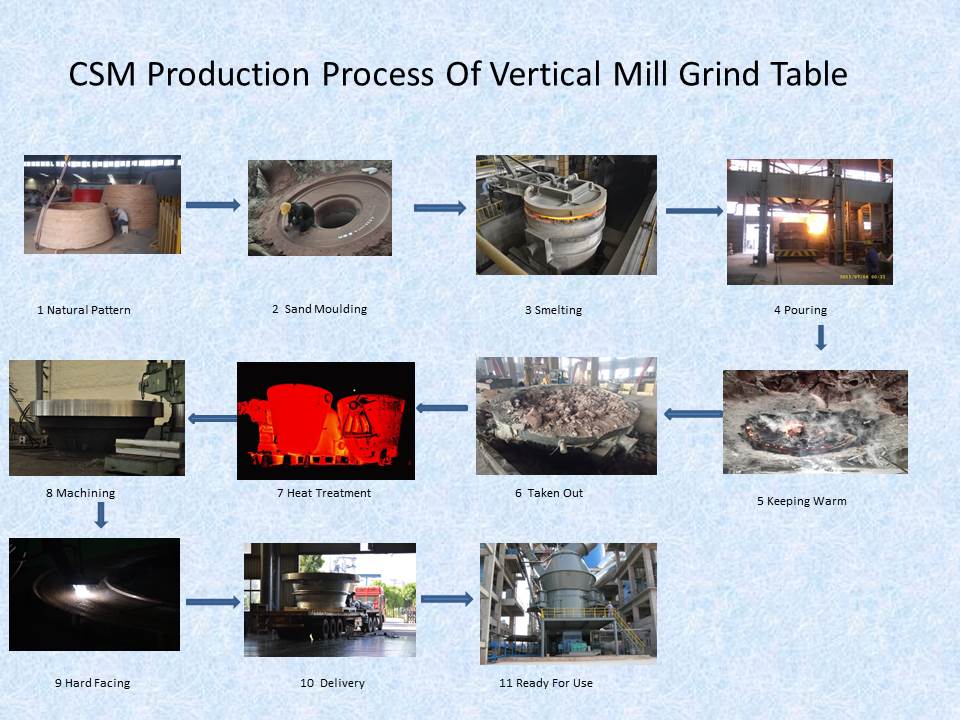

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

Product detail pictures:

Related Product Guide:

Steve Howey slaughters Mike Ashley for his running of Newcastle United | Slag Pots

What It Would Really Take To Sink A Modern Aircraft Carrier | Slag Pots

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Manufacturing Companies for 1000kg Copper Scrap Smelting Furnace - Ball Mill End Cover, Stationary Inlet and Outlet – Special Metal, The product will supply to all over the world, such as: Portland , Plymouth , Botswana , We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.