Manufacturer for Resistance To Cracking - Rope Sheave – Special Metal Detail:

Sheaves, Pulley in Cast Steel

Expertise products made in China

Product definition

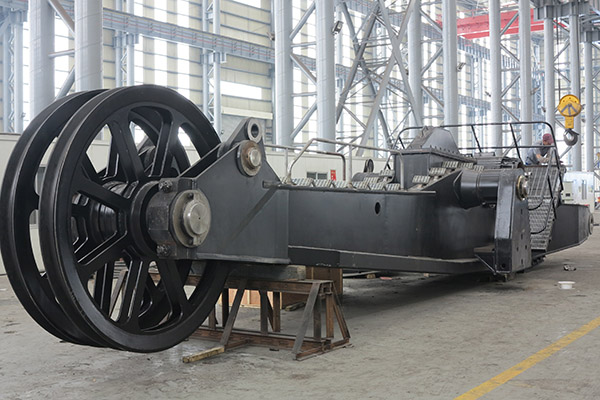

The product covered here is a dragging device which is installed in the derrick, and support the mine hoist, hoist support drag between the rolls to enhance the container, and guide the use of wire rope steering. Rope groove is with plastic lining or plastic block, which will increase the service life of wire rope.

Material

This material is the casting steel G42CrMo4 ISO14737:2003(E), which is a fully killed steel, vacuum-degassed and processed to a fine grain size structure with improved properties both in toughness and in elongation.

- Chemical composition: (%)

|

Elements |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

V |

Cu |

|

Required |

0.38-0.45 |

≤0.6 |

0.6-1 |

0.025 |

0.02 |

0.8-1.2 |

0.15-0.25 |

≤0.4 |

≤0.05 |

≤0.3 |

- Mechanical properties

Checked at room temperature in the delivery condition i.e. after completion of the quality heat treatment from cylindrical cast-on test blocks (∅ 60 mm x 250 mm) available on every Sheaves: both the sample preparation and the testing comply with ASTM A 370-96.

|

Properties |

Yield strength |

Tensile strength |

Elongation |

Impact Value |

|

Required |

≥650 |

≥790 |

≥10 |

27 |

- Delivery condition: Hardening and tempering.

Manufacturing

All operations are carried-out at the in-house foundry plant.

- Molding

The castings are manufactured in a workman-like manner as required in the German standard DIN EN

1599-1: August 1997, ruling the delivery conditions of castings. The molding is individually carried out within a modular flask by using a sand preparation based on resin bonding.

- Melting

The melting is carried out in the oxygen steel plant ( 2 off 180 t BOF converters ); the ladle capacity allows a continuous bottom pouring process the speed of which is permanently controlled. The metal analysis is checked by using a computer linked spectrograph.

- Heat treatment

Every sheave undergoes a combined quality heat treatment (Hardening and tempering) aiming both to grain refining and to stress relieving.

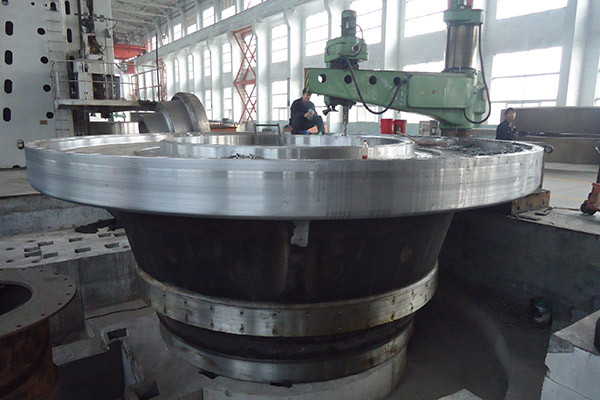

- Rough machining

In order to meet the inside quality free of defect, we rough machine each sheave foe inner NDT control.

- NDT testing

UT: ASTM A609 Level Ⅱ for the groove and boss center.

MT: 100% ASTM A125 level Ⅰ

- Fine machining

Fine machine every sheave totally according to drawings.

- Fettling and dressing

The castings are coated by antirust oil FPC-600 for transportation.

Delivery

Every sheave is packed well and ready for delivery.

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000.

The standard documentation ensures the full traceability of every process step:

- Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

- Dimensional check supported with a “as-built“ sketch;

- Record of the quality heat treatment;

Service philosophy

We endeavor to propose options in terms of design engineering in taking advantage of our double experience as manufacturer, always targeting the optimization of their service life.

Skill with sheave

Further information on delivery program as well as useful advises on product, design, material and application are provided by the customer service team of the foundry department: it will support you actively in helping you to elaborate the right solution.

Whenever you need assistance, please contact:

Emily Liu Phone: +86 13918839495 Facsimile: +86 21 33847960 Sales2@special-metal.com

Product detail pictures:

Related Product Guide:

Mother and son in UK-Cyprus drug ring | Copper Foil Manufacturing Facilities

High-end Copper Foil(Less than 10 ?m) Market 2018| Global Market Status( 2013-2017) and Forecast(2018-2025) | Copper Foil Manufacturing Facilities

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for Manufacturer for Resistance To Cracking - Rope Sheave – Special Metal, The product will supply to all over the world, such as: Israel , Rome , Kuwait , During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.