Leading Manufacturer for Wet Double Coal Pan Mill - Riding wheel for rotary kiln – Special Metal Detail:

Riding wheel for rotary kiln

Weight:7~42T

Applicable device: Rotary Kilns

Application: Cement, metallurgy, chemical, construction industries, etc

Customizable: Yes

Product introduction

Our main material for the Riding wheel for rotary kiln is similar to followings:

|

Standard Specifications for Cast Steel ZG55 |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS3100 | A5 |

| USA | AISI/SAE | UNS J05000 |

| Germany | / | / |

| Japan | / | / |

| International | ISO 3755:1991 | 340-550 |

|

Standard Specifications for Cast Steel ZG42CrMo |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS 970-1 | 708A42 |

| USA | ASTM A29/A29M | 4140/4142 |

| Germany | EN10083-1 | 42CrMo4 |

| Japan | JIS G4053-2003 | SCM440 |

| International | ISO 683/1 | 3 |

Advantages:

1. Large load bearing, good continuous operation performance

We CSM riding wheel are made from ZG55 and ZG42CrMo. This kind of material guarantee the quality of riding wheel, and also make riding wheel large loading bearing and good continuous operation performance.

2. Simple structure, convenient to adjust and maintain.

This kind of riding wheel uses rolling bearing wheel sets, and is simple in structure and convenient to maintain.

3. Heat treated through normalizing and tempering, hardness of riding wheel is higher.

We CSM apply normalizing and tempering heat, which makes riding wheel’s outer surface hardness higher than 200HB; guarantee the quality of riding wheel for rotary kiln.

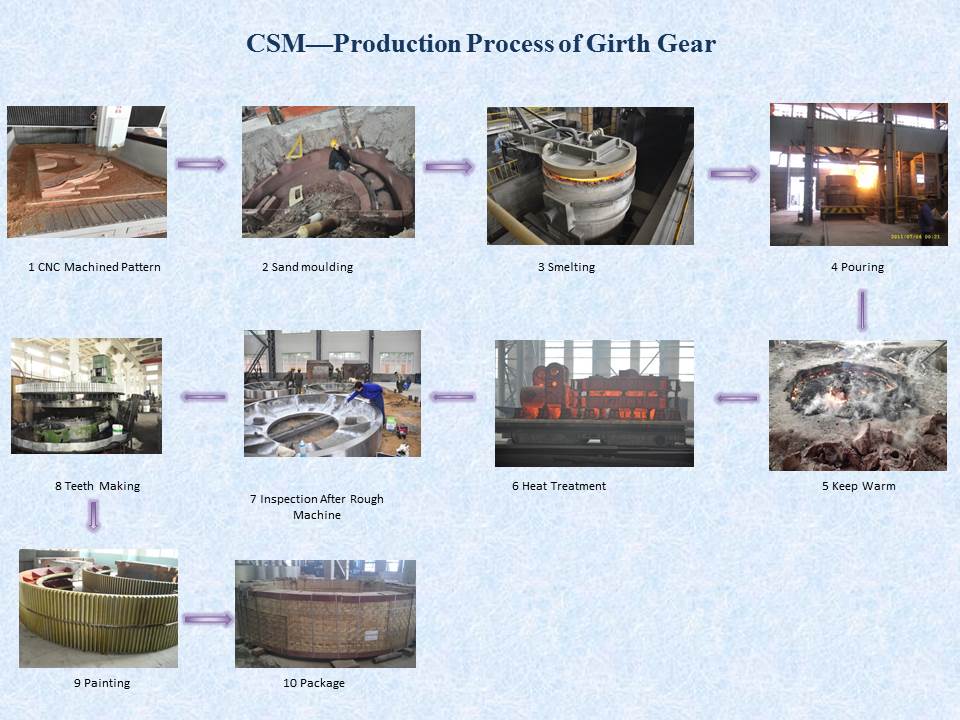

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

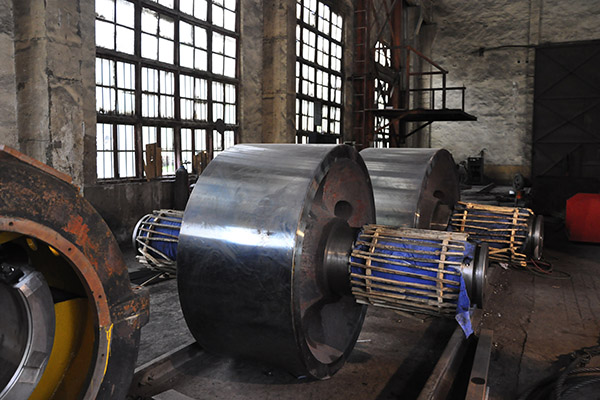

Picture:

Product detail pictures:

Related Product Guide:

Global Copper Foil Shielding Tape Market 2018 (Sales & Key Players) – 3M, Alpha Wire, Tapes Master, Shielding Solutions, Nitto, Hilltop Products, Hilltop Products | Copper Foil Manufacturing Facilities

DUNMORE Announces New DUN-SOLAR⢠Photovoltaic Backsheets | Single Stage Hammer Crushers

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Leading Manufacturer for Wet Double Coal Pan Mill - Riding wheel for rotary kiln – Special Metal, The product will supply to all over the world, such as: Ireland , Istanbul , Manchester , It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we'll be happy to serve you.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.