Hot-selling Tilting Type Melting Furnace - Transfer Ladle in Smelting Workshop Crucible – Special Metal Detail:

Introduction

Crucibles are cast steel molds for the casting of aluminum ingot for remelt storage and/ or transportation. Dimensions and design can be customized to customer requirements, including the casting of customer’s logo, and additional of feet and/or lugs for material handling.

INDUSTRIES : Cast houses; Remelter

APPLICATIONS : Cast ingot Solid storage/ transportation Empty trough / furnace

MATERIAL AVAILABLE : QT450-12/ASTM A536/65-45-12

Shanghai Special Metal Co., Ltd is a comprehensive and professional supporting supplier in industrial field which owns great production capacity, advanced management ability, splendid procedure control system and first rate service so that we can provide high quality products as well as service to the worldwide customers.

In principle there are three sorts of materials available for the manufacture of crucibles: Grey Cast Iron, Spheroidal Graphite (S.G.) Iron and Cast Steel.

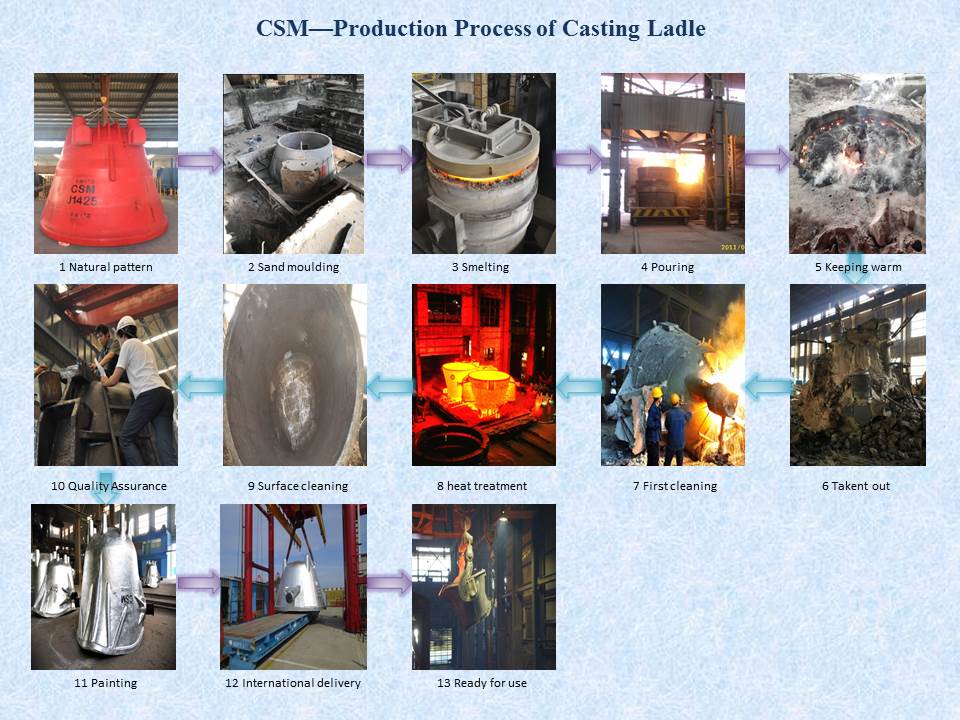

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

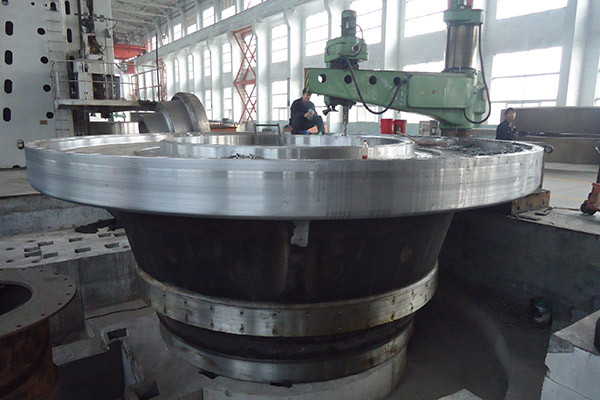

Pictures:

Product detail pictures:

Related Product Guide:

Archaeologists dig up historic treasure in Peddabonkur Facebook Twitter Google+ LinkedIn WhatsApp Pinterest Facebook Twitter Google+ LinkedIn WhatsApp Pinterest | Single Stage Hammer Crushers

Chinese prof in child porn case also under scrutiny in spy probe | Copper Foil Manufacturing Facilities

As for aggressive costs, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such high-quality at such rates we have been the lowest around for Hot-selling Tilting Type Melting Furnace - Transfer Ladle in Smelting Workshop Crucible – Special Metal, The product will supply to all over the world, such as: moldova , Bangalore , Jakarta , we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!