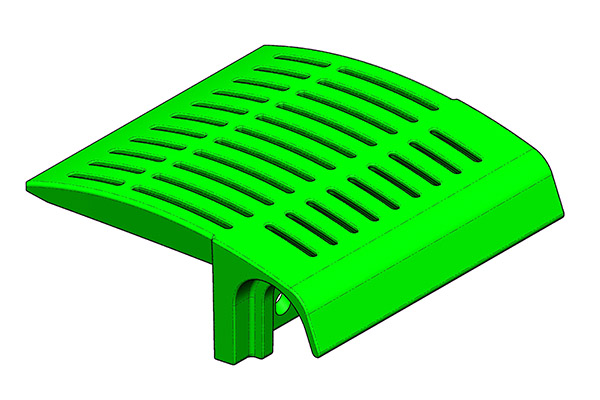

Hot Selling for Peeling And Grinding Machine - Chain grating machine Grate Plate – Special Metal Detail:

Product Introduction

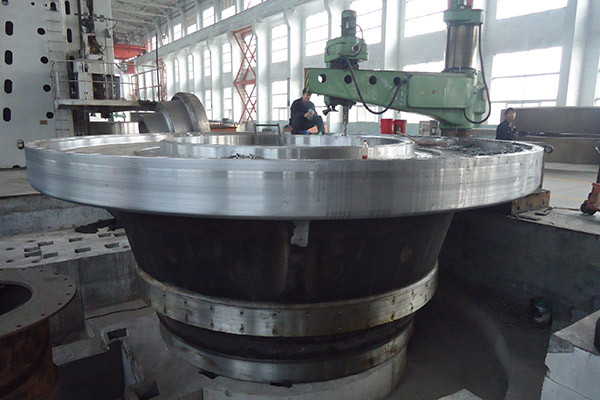

The grate castings cycle through the grate furnace on a continuous cycle and carry the magnetite iron ore pellets through the process and into the kiln.

Processing Steps:

· In the first section of the grate furnace (drying) the temperatures are fairly low (around 200C to 240C),

· In the second section of the furnace (dehydration) the temperature are higher (around 480C to 520C),

· In the third section of the furnace (pre-heat 1) the process temperature rises (980C to 1020C),

· n the final section of the furnace (pre-heat 2) the process temperature reaches its maximum (1050C to 1100C)

· After the preheat 2 section the grate castings discharge their pellets into the kiln and then run along the return side of the grate in ambient air where they cool down before getting loaded with pellets again and entering the furnace for the next cycle.

The temperatures above are the process gas temperatures that the castings are exposed to. The castings themselves would not quite reach these temperatures and would be slightly cooler.

The thermal cycling of the grate castings is continuous as it cycles through the grate during production.

The maximum temperature of the casting goes to approximately 650C when it discharges its load into the kiln and then the castings cool down to approximately 150C in free air, as it returns to the tail end.

Shanghai Special Metal Co., Ltd supplies very high wear grates for mining environments to maximize its life.

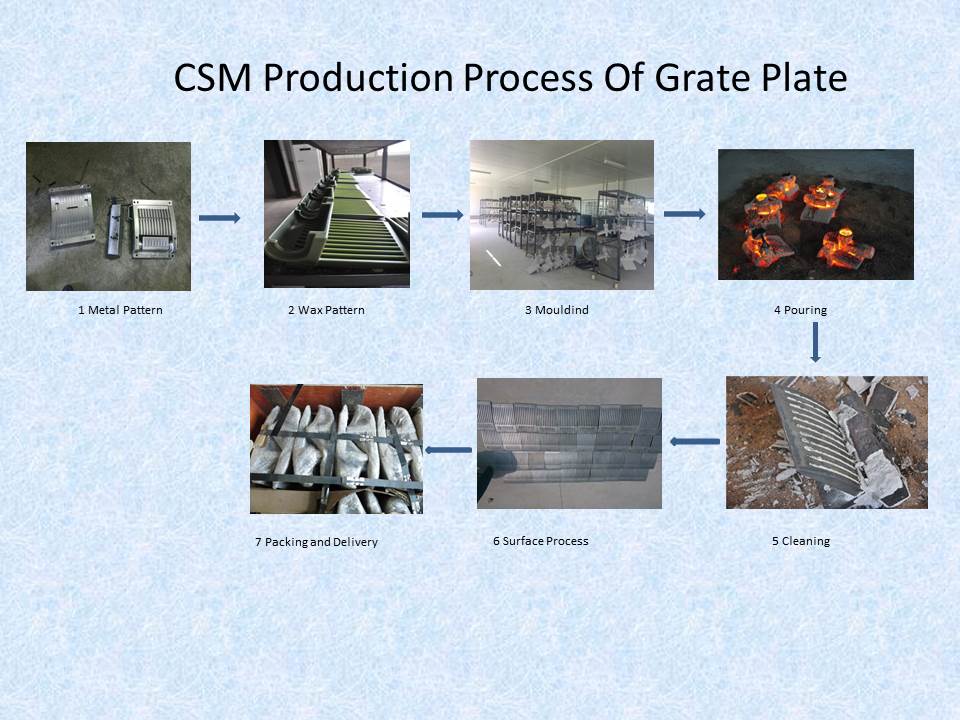

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

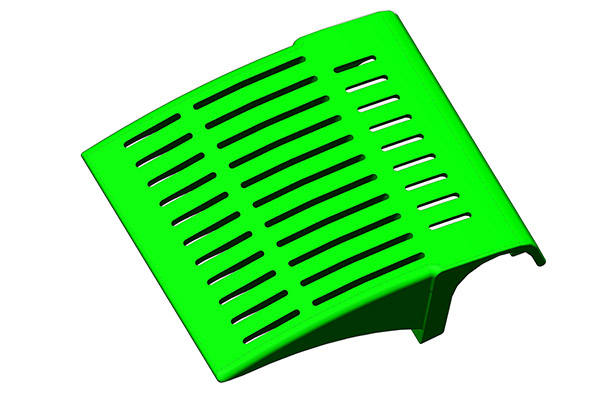

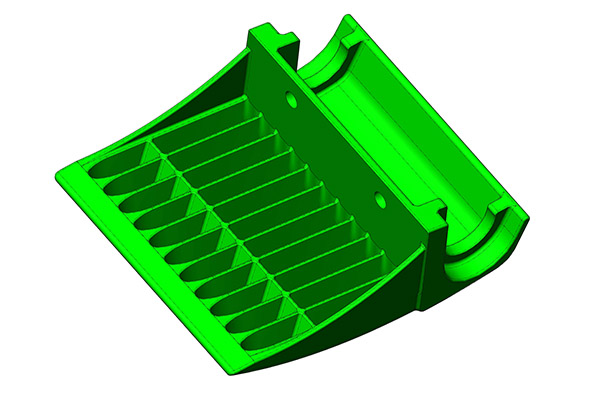

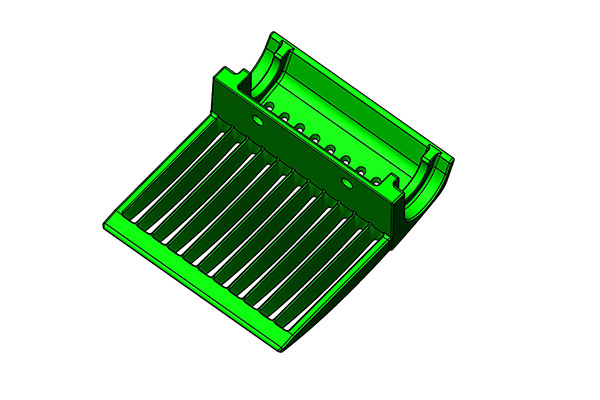

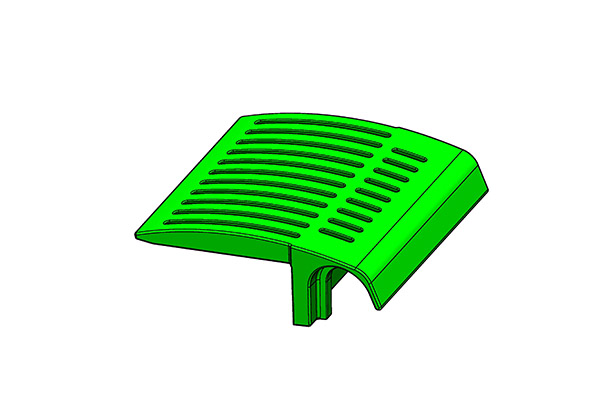

pictures:

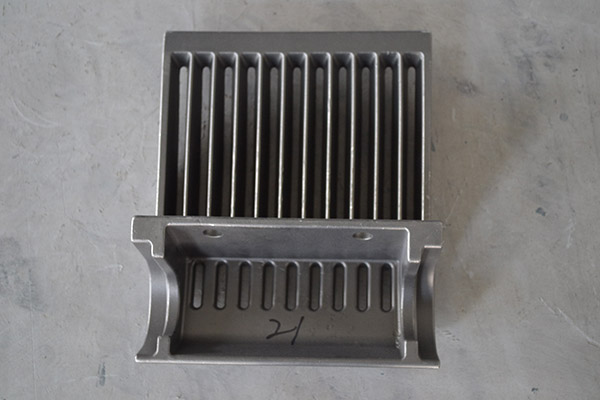

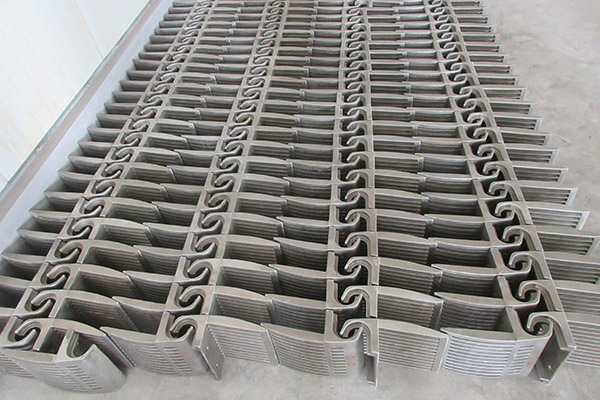

Product detail pictures:

Related Product Guide:

For Welding Certain Metals, Blue Lasers Offer the Advantage | Features | Oct 2018 | Single Stage Hammer Crushers

Waterbury Metals Factory Spills More Than 1,000 Gallons Of Oil Into Naugatuck River | Slag Pots

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for Hot Selling for Peeling And Grinding Machine - Chain grating machine Grate Plate – Special Metal, The product will supply to all over the world, such as: Costa Rica , Swaziland , Zurich , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!