Hot Sale for Chain Connecting Link - Copper Foil Manufacturing Facilities – Special Metal Detail:

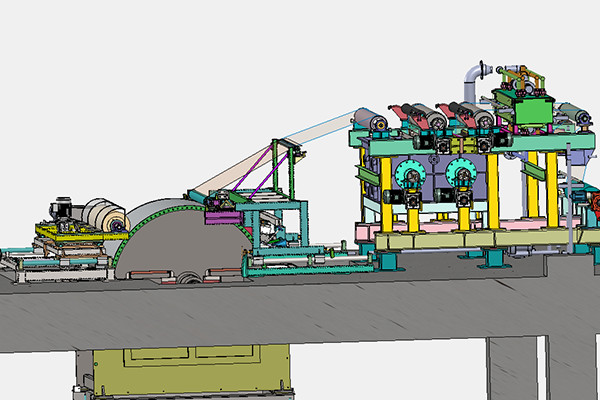

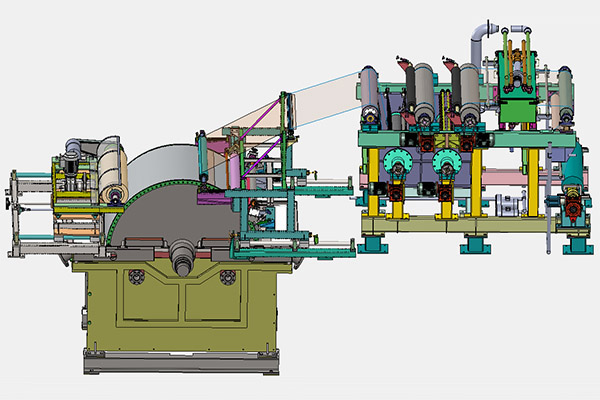

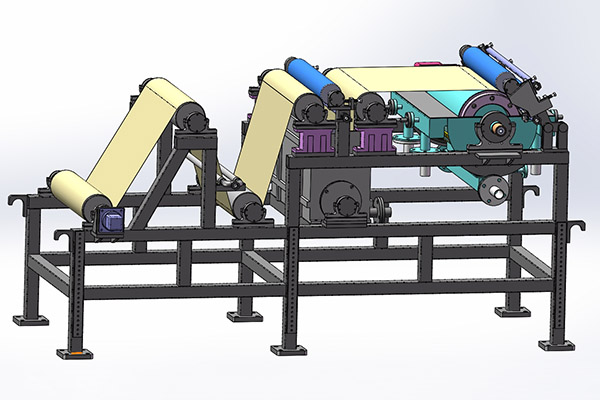

Copper foil integrated machine assembly line

- The only four-roller spinning rolling machine in the industry :The maximum spinning diameter is 3.8 meters and the length is 1.7 meters. This type of rolling machine can furtherly optimize the shape, surface and precision of the cathode roll.

- The control technology of impurity content of ingots: Through the strict and precise control of impurity elements, the precise control of ingots composition can be realized by the vacuum melting process, and the high-quality titanium ingot with low impurity elements can be obtained through the strict parameter control of the raw material of sponge titanium and the smelting implementation process.

- The control technology of the tissue uniformity: Through the forging, rolling and hot treatment process, the billet achieves a full refinement, and establish the fine-grained tissue foundation. Electrode position drum avoids the formation of “spotted spots” on the surface.

- The control technology of rolling tissue uniformity: Through the large-tonnage, two-way Computerized Numerical Control rolling mill to form ring parts, and through the parameter optimization (rolling temperature and deformation) and the reasonable distribution of processing volume to ensure the effect of tissue refinement and the consistency of various parts . The final control objective is that the average grain size of the finished ring parts reaches GB/T6394-2002 grade5~6, and the ultrasonic test meets the GB/T5193-2007 AA level.

- The control technology of Spin-formed tissue consistency: Through the stable standardized spin-formed process, and using large-diameter thin-wall isothermal spin-formed technology, the metal tissue dynamic recrystallization during machining process can be realized through the mold and billet insulation technology and the optimization of the control rolling frequency deformation. The tissue uniformity and consistency of the titanium electrode position drum are the key factors for the stable preparation of high quality copper foil.

Product detail pictures:

Related Product Guide:

These Ancient Clay Jars Could Solve The Mystery of Earth’s Magnetic Field | Slag Pots

These 12 states are getting hit hardest by Trumpâs tariffs | Cast Steel Nodes

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Hot Sale for Chain Connecting Link - Copper Foil Manufacturing Facilities – Special Metal, The product will supply to all over the world, such as: Hyderabad , Bangladesh , Southampton , because of our company has been persisting in the management idea of "Survival by Quality, Development by Service, Benefit by Reputation" . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

Agree with this Privacy Policy.