Hot sale Factory Pellet Machine Of Animal Feed - Transfer Ladle in Smelting Workshop Casting ladle – Special Metal Detail:

In the metallurgical and melting fields, a ladle is a vessel used to transport high temperature metal or pour out molten metals. Usually it has three different types, for example, casting ladle, transfer ladle, treatment ladle. Ladles are normally rated by their working capacity rather than by their physical size.

Casting ladle: a ladle used to pour molten metal into moulds to produce the casting.

Transfer ladle: a ladle used to transfer a large amount of molten metal from one process to another. Typically a transfer ladle will be used to transfer molten metal from a primary melting furnace to either an holding furnace or an auto-pour unit.

Treatment ladle: a ladle used for a process to take place within the ladle to change some aspect of the molten metal. A typical example being to convert cast iron to ductile iron by the addition of various elements into the ladle.

MATERIAL

We CSM ladles are made from Cast Steel, which is similar to the following standards, we will offer the material specification as you required.

|

Standard Specifications for Cast Steel |

||

|

Country |

Standard |

Grade |

|

United Kingdom |

BS 3100:1991 |

425-A2 |

|

USA |

ASTM A 27 |

60-30 |

|

Germany |

DIN 17182 |

GS-16Mn5 |

|

Japan |

JIS G7821:2000 |

SC42 |

|

International |

ISO 3755:1991 |

230-450 |

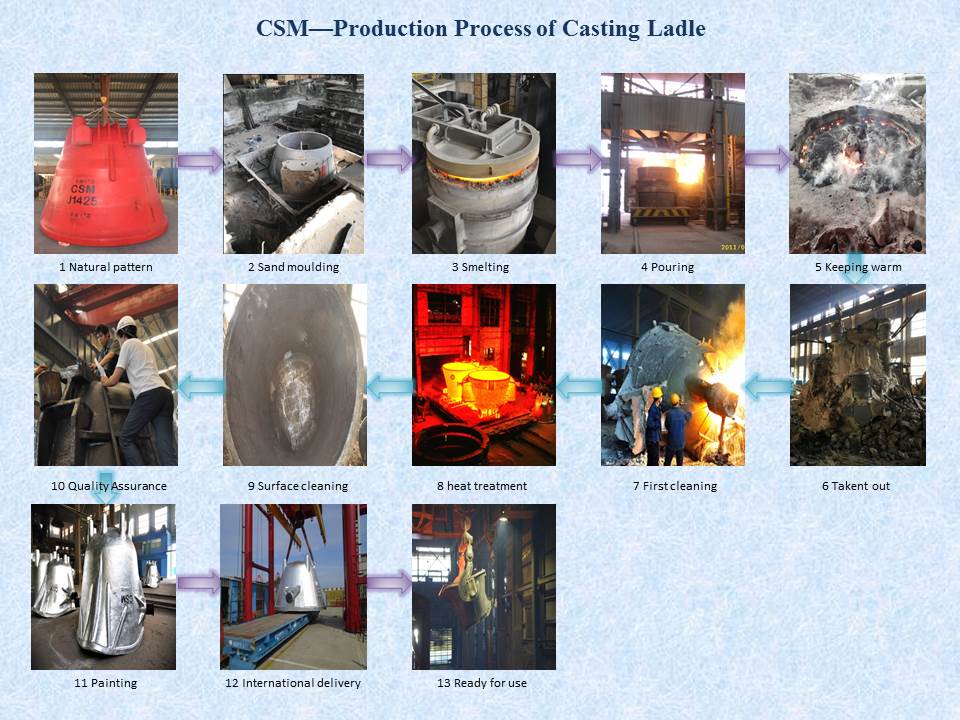

Production Process

Pictures:

Product detail pictures:

Related Product Guide:

Evertiq – A problem that might worsen | Single Stage Hammer Crushers

AT&T Ignores Numerous Pitfalls, Begins Kicking Pirates Off Of The Internet | Cast Steel Nodes

We've been commitment to offer the competitive rate ,outstanding merchandise good quality, too as fast delivery for Hot sale Factory Pellet Machine Of Animal Feed - Transfer Ladle in Smelting Workshop Casting ladle – Special Metal, The product will supply to all over the world, such as: Durban , Mozambique , Rio de Janeiro , All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.