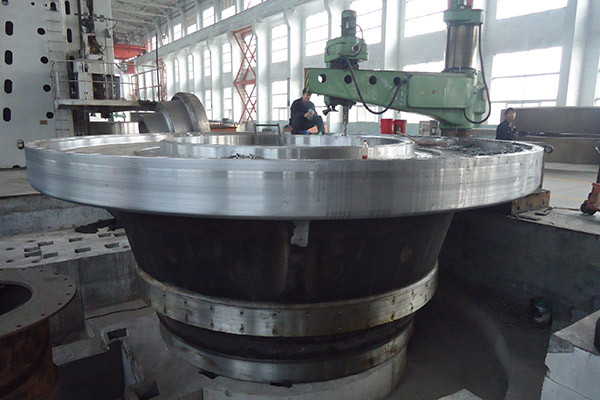

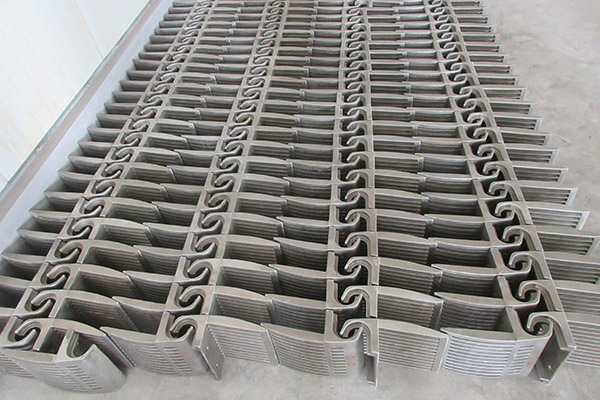

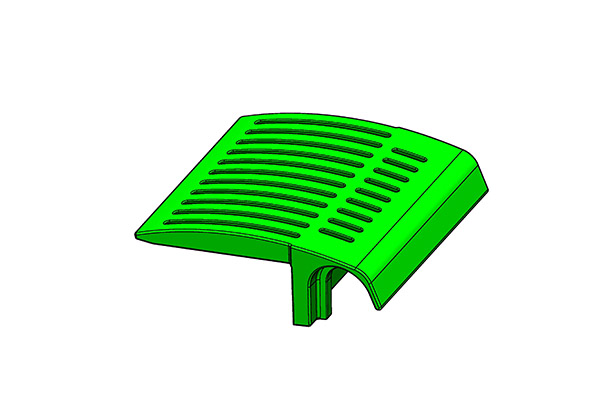

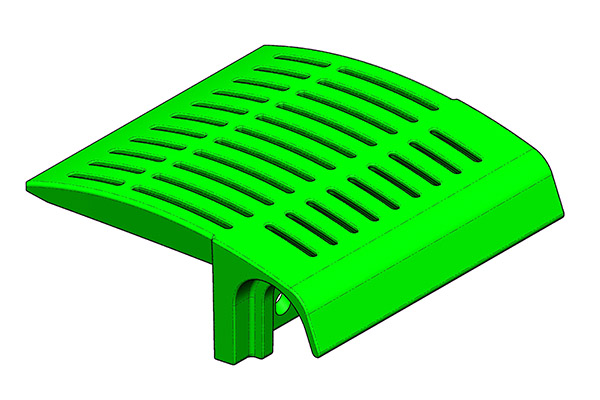

High Quality Rolling Mill Housing - Chain grating machine Grate Plate – Special Metal Detail:

Product Introduction

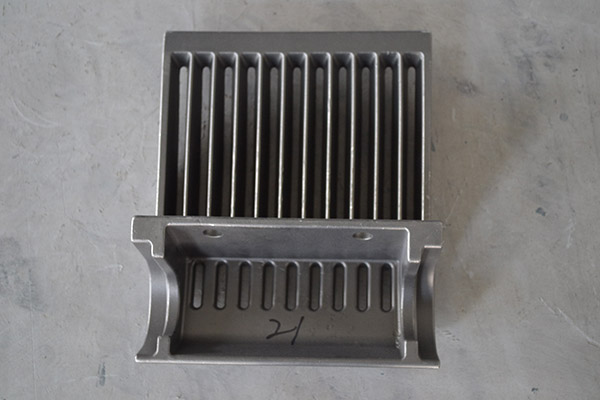

The grate castings cycle through the grate furnace on a continuous cycle and carry the magnetite iron ore pellets through the process and into the kiln.

Processing Steps:

· In the first section of the grate furnace (drying) the temperatures are fairly low (around 200C to 240C),

· In the second section of the furnace (dehydration) the temperature are higher (around 480C to 520C),

· In the third section of the furnace (pre-heat 1) the process temperature rises (980C to 1020C),

· n the final section of the furnace (pre-heat 2) the process temperature reaches its maximum (1050C to 1100C)

· After the preheat 2 section the grate castings discharge their pellets into the kiln and then run along the return side of the grate in ambient air where they cool down before getting loaded with pellets again and entering the furnace for the next cycle.

The temperatures above are the process gas temperatures that the castings are exposed to. The castings themselves would not quite reach these temperatures and would be slightly cooler.

The thermal cycling of the grate castings is continuous as it cycles through the grate during production.

The maximum temperature of the casting goes to approximately 650C when it discharges its load into the kiln and then the castings cool down to approximately 150C in free air, as it returns to the tail end.

Shanghai Special Metal Co., Ltd supplies very high wear grates for mining environments to maximize its life.

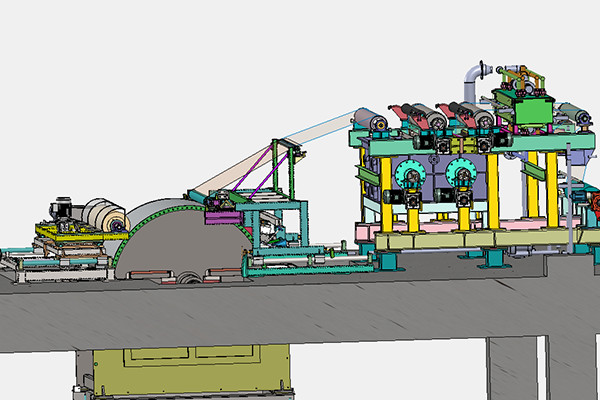

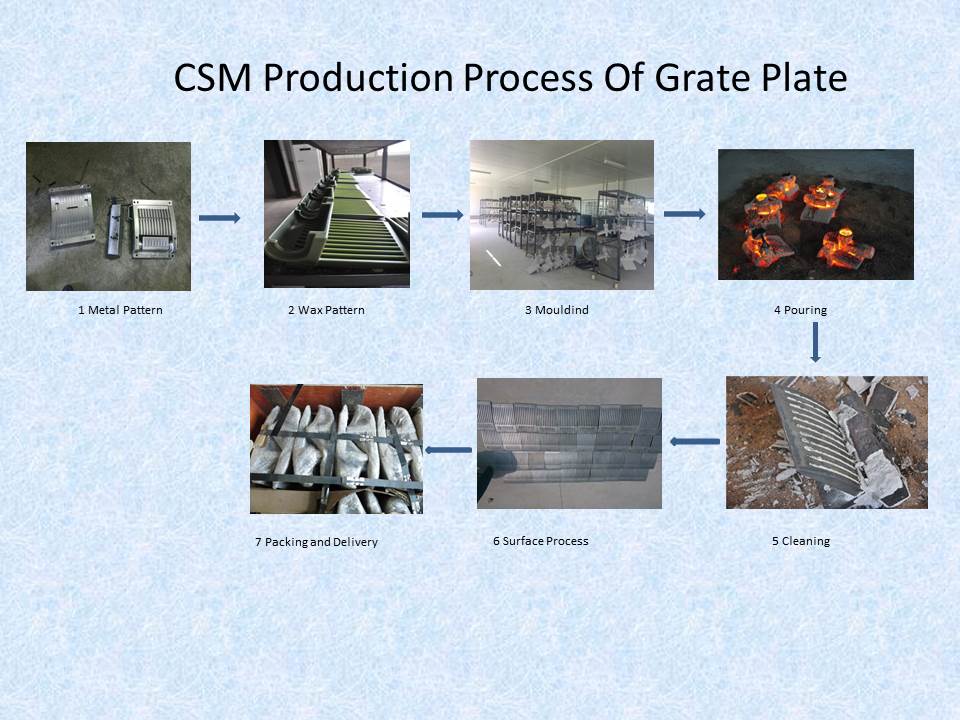

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

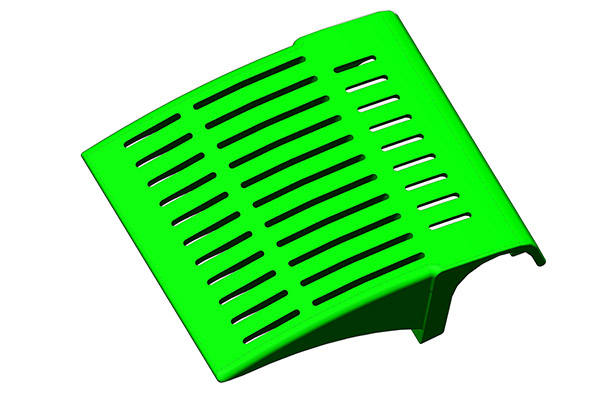

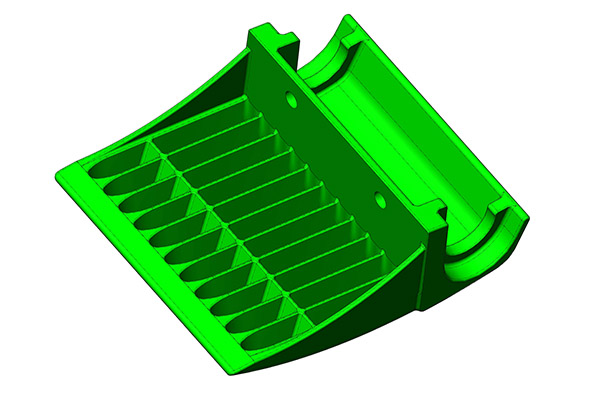

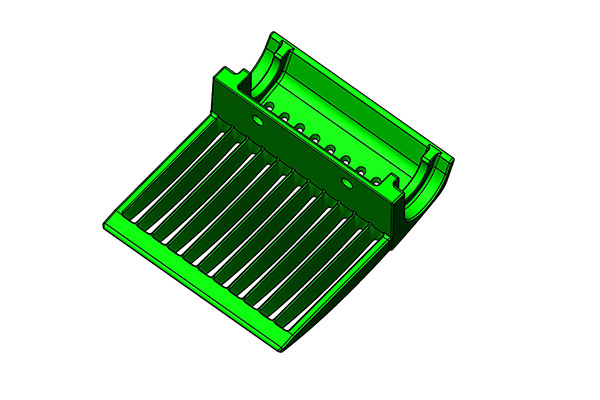

pictures:

Product detail pictures:

Related Product Guide:

Global Copper Powder Market Insights 2018-2024: GGP Metalpowder, SCM Metal Products, UMMC, Umcor, Fukuda Metal Foil & Powder | Cast Steel Nodes

West Nile Virus present in Lowndes | Local News | Cast Steel Nodes

While using the "Client-Oriented" organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for High Quality Rolling Mill Housing - Chain grating machine Grate Plate – Special Metal, The product will supply to all over the world, such as: Israel , Swiss , Malaysia , Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.