High Quality Foundry Ladle Launder - Vertical Mill and Spare Parts Vertical mill rocker arm – Special Metal Detail:

Vertical mill rocker arm

Weight: 10-25T

Applicable devices: vertical mills, mineral slag vertical mills, cement vertical mills, steel slag vertical mills, nickel slag mills, raw material vertical mills and coal vertical mills.

Application: Cement, building material, chemical, coal, electricity, metallurgy and non-metallic mine

Customizable: Yes

Introduction

Rocker arm is the main part of vertical mill. It is composed of upper rocker arm, down rocker arm, rocker arm shaft, bearing and bearing block. Upper rocker arm is used to install mill roller, down rocker arm is to connect hydraulic system. These two rocker arms are integrated as a unit through shaft, taper sleeve and taper pin.

Our main material for vertical mill rocker arm is similar as followings:

|

Standard Specifications for Cast Steel |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS3100 | A2 |

| USA | AISI/SAE | UNS J04000 |

| Germany | DIN 1681 | GS-60 |

| Japan | JIS-G5101 | SC480 |

| International | ISO 3755 | 270-480 |

Advantage

1. Vertical mill rocker arm from SHANGHAI SPECIAL METAL CO., LTD is good in wear resistance and anti-cracking

2. Arc air gouging and shot blasting are used to casting steels’ finishing, to make sure good appearance quality.

3. SHANGHAI SPECIAL METAL CO., LTD promise: will do NDE inspections by professional testers before delivery, refuse any inferior and defective products to be delivered.

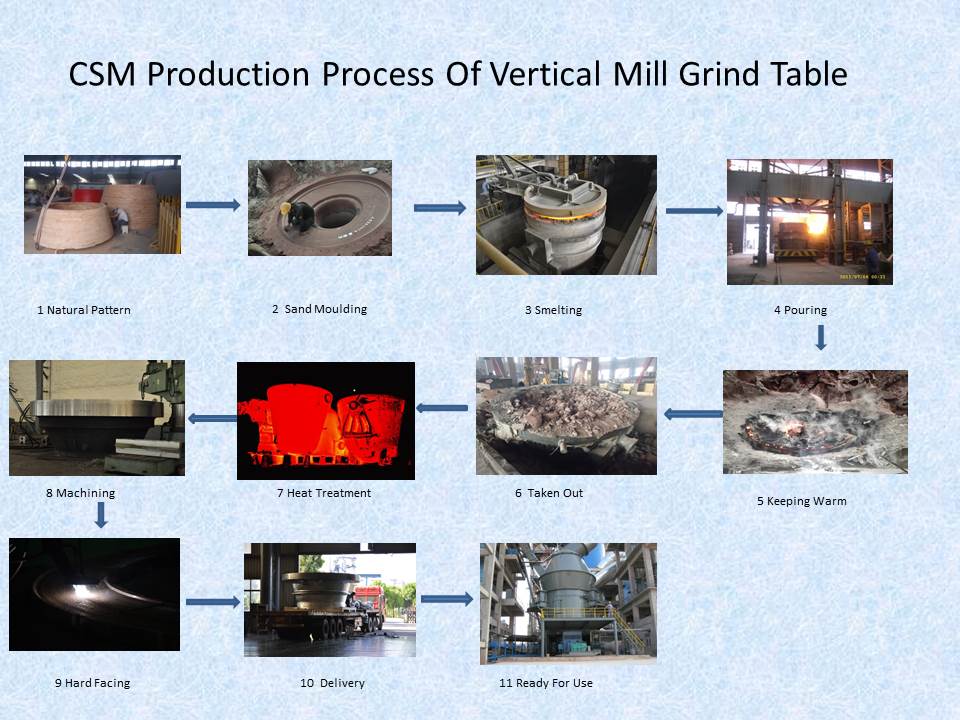

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

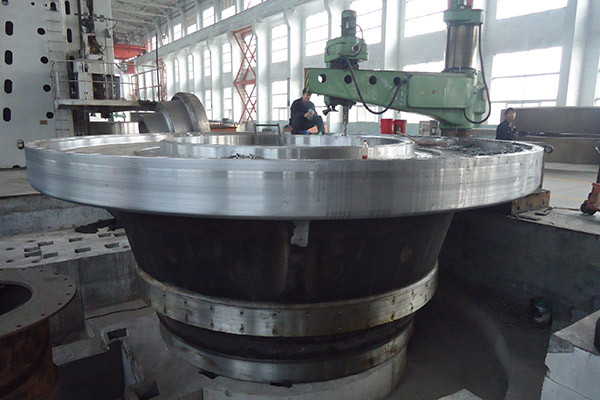

Pictures:

Product detail pictures:

Related Product Guide:

On this day in Alabama history: Industrialist James Sloss died | Slag Pots

Global High-end Copper Foil Market Insights 2018-2025: Mitsui Mining & Smelting, Furukawa Electric, JX Nippon Mining & Metal, Fukuda | Cast Steel Nodes

Every single member from our higher effectiveness product sales staff values customers' requires and organization communication for High Quality Foundry Ladle Launder - Vertical Mill and Spare Parts Vertical mill rocker arm – Special Metal, The product will supply to all over the world, such as: Finland , Malaysia , Jamaica , The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!