High Quality for Cast Iron Electric Heaters - Chucks with or without Hydro-cylinder – Special Metal Detail:

Chocks

Weight: 3~20T

Applicable device: mill parts

Application: Cement, electricity, metallurgy, chemical and others

Customizable: Yes

Introduction

Bearing chock plays an important role of fixing bearing and bearing weight. It is the core part of rolling bearing. Its main function is to support the whole bearing structure.

Bearing chock works under low speed and heavy load for long time. So its reliability is the most important feature. To achieve this feature, it must require good quality of bearing chock.

Our main material for the bearing chock is similar as following

|

Standard Specifications for Cast Steel SCW480 |

||

|

Country |

Standard |

Grade |

| China | GB/T 11352-1989 | ZG20SiMn |

| United Kingdom | / | / |

| USA | AISI/SAE | UNS J02505 |

| Japan | JIS-G5102 | SCW480 |

| Germany | DIN 17182 | GS-20Mn5 |

| International | / | / |

Advantage

1. Fine material, high level of wear resisting

SHANGHAI SPECIAL METAL CO., LTD uses SCW480 to produce bearing chock, to ensure products’ quality. Through the test of practice, bearing chocks produced by SHANGHAI SPECIAL METAL CO., LTD can work well under long-time, heavy load operation with small wear loss.

2. Equipped with monitoring devices, can get operation condition at any time

Below bearing chock, there’s an oil leveler. Operator can view oil level at any time, supplement oil in time, avoid poor lubrication and bearing damage lead from oil lacking.

3. Reasonable structure, good for long-time and stable operation

Removed outside top cover, this design avoids dusts go into bearing box, improves bearing’s working life, and secures its work.

4. Holes of cylinder-oil with the degree of finish Ra 0.02

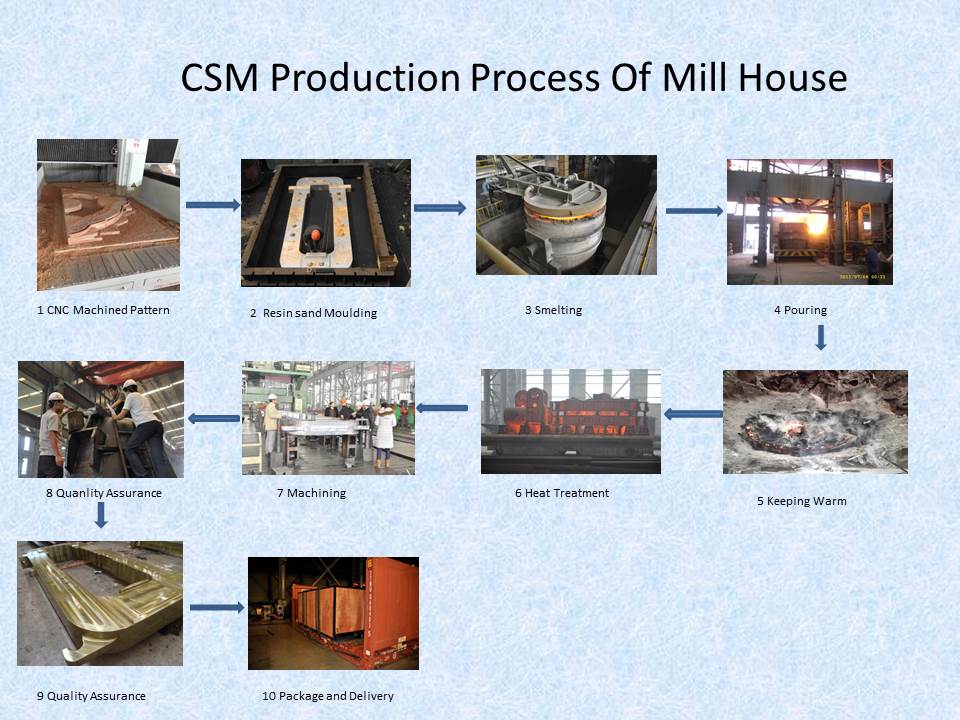

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

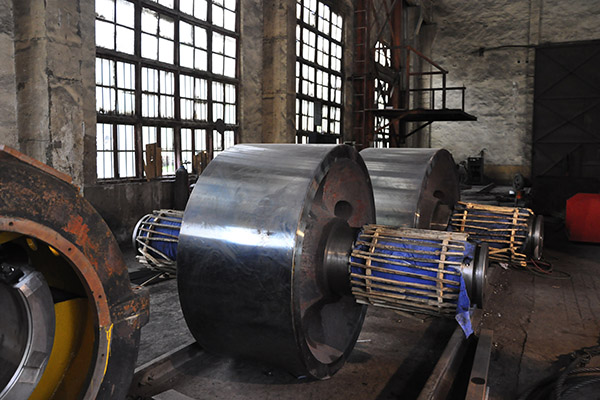

Pictures:

Product detail pictures:

Related Product Guide:

‘Kidney twins’ celebrating first holiday season after life-saving donation | Northwest Indiana Business Headlines | Single Stage Hammer Crushers

NBN Co rolls out capacity boost for transit network | Single Stage Hammer Crushers

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for High Quality for Cast Iron Electric Heaters - Chucks with or without Hydro-cylinder – Special Metal, The product will supply to all over the world, such as: Monaco , Ottawa , Bangkok , Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.