Factory Outlets 65-45-12 Ductile Iron Sand Casting - Ball Mill End Cover, Stationary Inlet and Outlet – Special Metal Detail:

Ball mill head

Shanghai Special Metal Co., Ltd supplies ball mill head. The materials of mill head are normally selected low carbon steel and low alloy steel. It’s produced by casting, used in ball grinding mill, including the feed end and outlet end, our head/cap for the bellow ball grinding mill.

Ball mill data:

| Model(mmxmm) | Speed of bucket(r/min) | Weight of ball(t) | Size of feed opening(mm) | Production(t/h) | Power(kw) |

| φ900×1800 | 38 | 1.5 | ≤20 | 0.65-2 | 18.5 |

| φ1200×2400 | 32 | 3.8 | ≤25 | 1.5-4.8 | 45 |

| φ1500×5700 | 27 | 15 | ≤25 | 3.5-6 | 132 |

| φ2200×5500 | 21 | 30 | ≤25 | 10-22 | 370 |

| φ2400×10000 | 20.8 | 49 | ≤25 | 22 | 630 |

| φ3000×13000 | 18.2 | 115 | ≤25 | 40-42 |

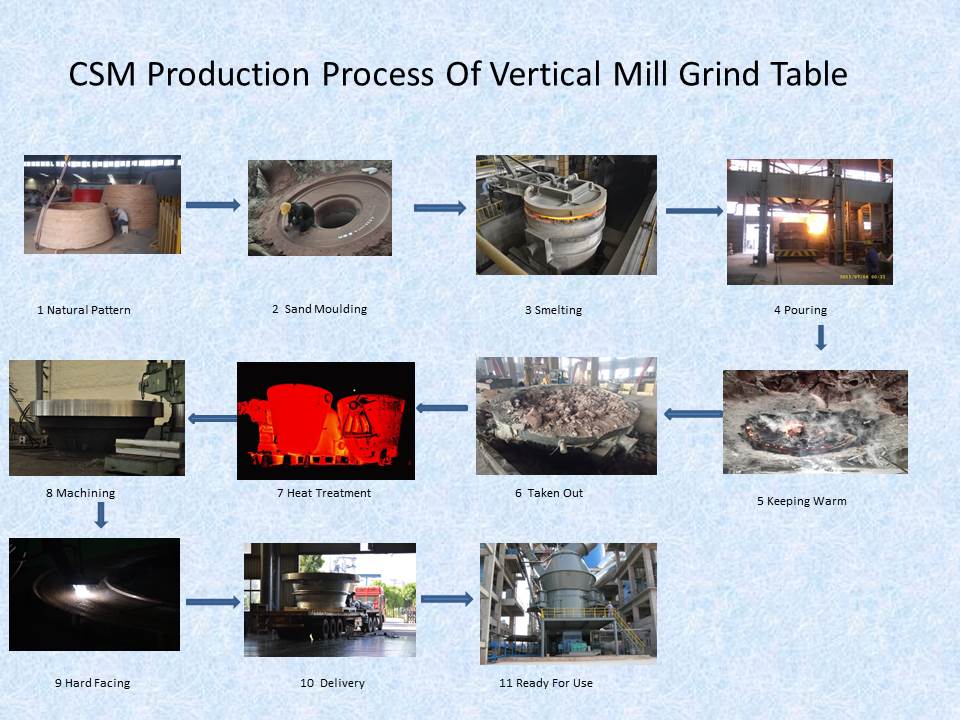

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

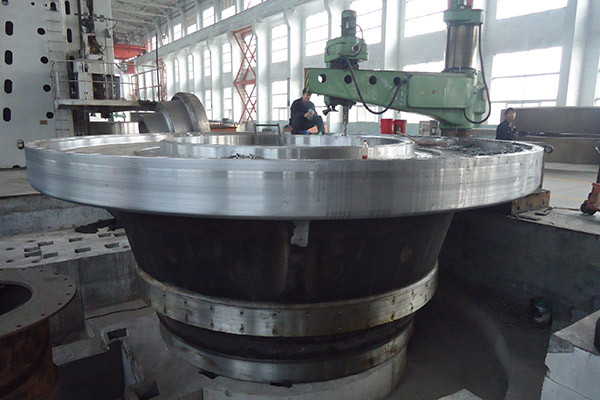

Product detail pictures:

Related Product Guide:

BHP’s book of the lost found | Single Stage Hammer Crushers

Global Copper Foil Tape Market 2019- Ampetronic, Teraoka Tape, 3M | Copper Foil Manufacturing Facilities

While using the "Client-Oriented" company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for Factory Outlets 65-45-12 Ductile Iron Sand Casting - Ball Mill End Cover, Stationary Inlet and Outlet – Special Metal, The product will supply to all over the world, such as: Greece , Bhutan , Niger , We are proud to supply our products to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.