Factory best selling Steel Foundry Equipment - Transfer Ladle in Smelting Workshop Crucible – Special Metal Detail:

Introduction

Crucibles are cast steel molds for the casting of aluminum ingot for remelt storage and/ or transportation. Dimensions and design can be customized to customer requirements, including the casting of customer’s logo, and additional of feet and/or lugs for material handling.

INDUSTRIES : Cast houses; Remelter

APPLICATIONS : Cast ingot Solid storage/ transportation Empty trough / furnace

MATERIAL AVAILABLE : QT450-12/ASTM A536/65-45-12

Shanghai Special Metal Co., Ltd is a comprehensive and professional supporting supplier in industrial field which owns great production capacity, advanced management ability, splendid procedure control system and first rate service so that we can provide high quality products as well as service to the worldwide customers.

In principle there are three sorts of materials available for the manufacture of crucibles: Grey Cast Iron, Spheroidal Graphite (S.G.) Iron and Cast Steel.

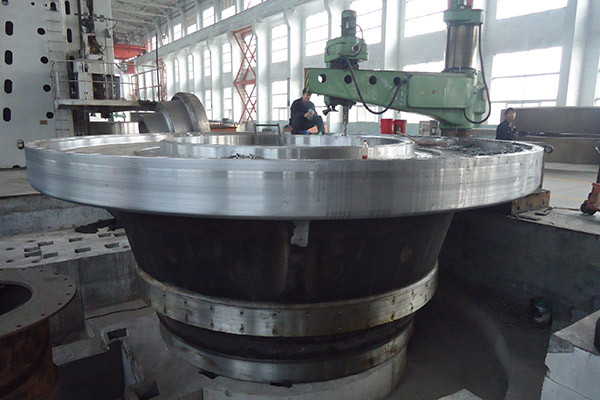

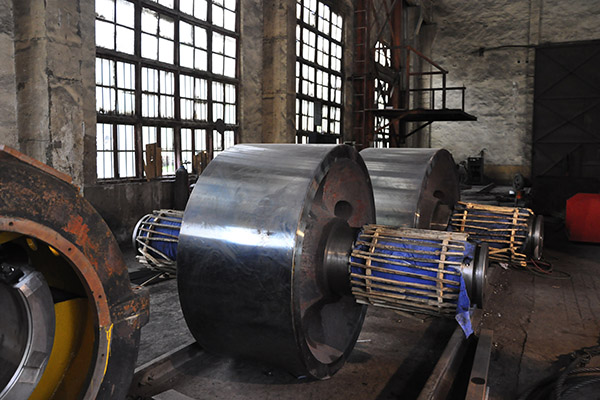

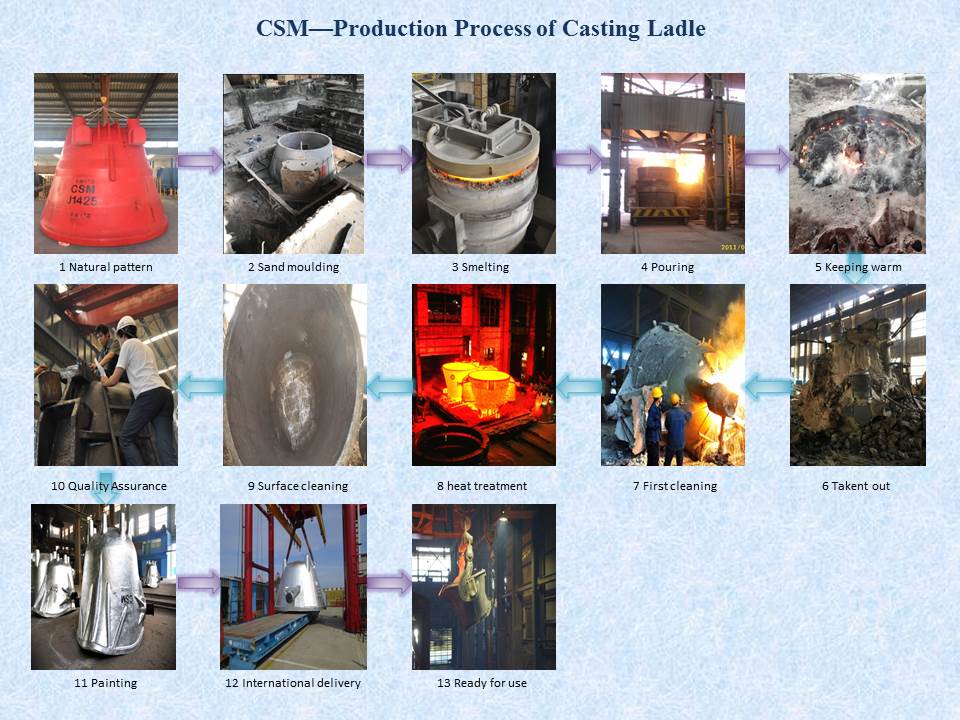

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

Pictures:

Product detail pictures:

Related Product Guide:

LG Chem expands production of electric car batteries in Polish plant | Slag Pots

The beautiful Northumberland landscape which was once a powerhouse of North East industry | Cast Steel Nodes

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of Factory best selling Steel Foundry Equipment - Transfer Ladle in Smelting Workshop Crucible – Special Metal, The product will supply to all over the world, such as: Lyon , Albania , Wellington , We believe in quality and customer satisfaction achieved by a team of highly dedicated individuals. The team of our company with the use of cutting-edge technologies delivers impeccable quality products supremely adored and appreciated by our customers worldwide.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.