Discount wholesale New Foundry Casting Lip Pouring Ladle - Vertical Mill and Spare Parts vertical mill hub – Special Metal Detail:

Vertical mill hub

Weight: 5~30T

Applicable devices: all types of vertical mills, mineral slag vertical mills, cement vertical mills, steel slag vertical mills, nickel slag mills, raw material vertical mills and coal vertical mills.

Application: Cement, building material, chemical, coal, electricity, metallurgy, non-metallic mine, etc

Customizable: Yes

Product introduction

Hub is the core part of grinding roller. Roller shell is fixed on hub, and hub is installed on roller shaft, then they make up a set of grinding roller. Generally, between roller shell and hub, there’s a cone structure, to ensure the convenience of maintenance and dismounting.

Our main material for the Vertical mill hub is similar to followings:

|

Standard Specifications for Cast Steel ZG270-500 |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS3100 | A2 |

| USA | AISI/SAE | UNS J04000 |

| Germany | DIN 1681 | GS-60 |

| Japan | JIS-G5101 | SC480 |

| International | ISO 3755 | 270-480 |

Advantage

1. Casted hubs from Shanghai Special Metal Co., Ltd are wear resisting and not easy to crack.

2. Shanghai Special Metal Co., Ltd insists: before delivery, professional QCs should do NDE inspections several times on hub’s stress face, refuse any inferior products to be delivered.

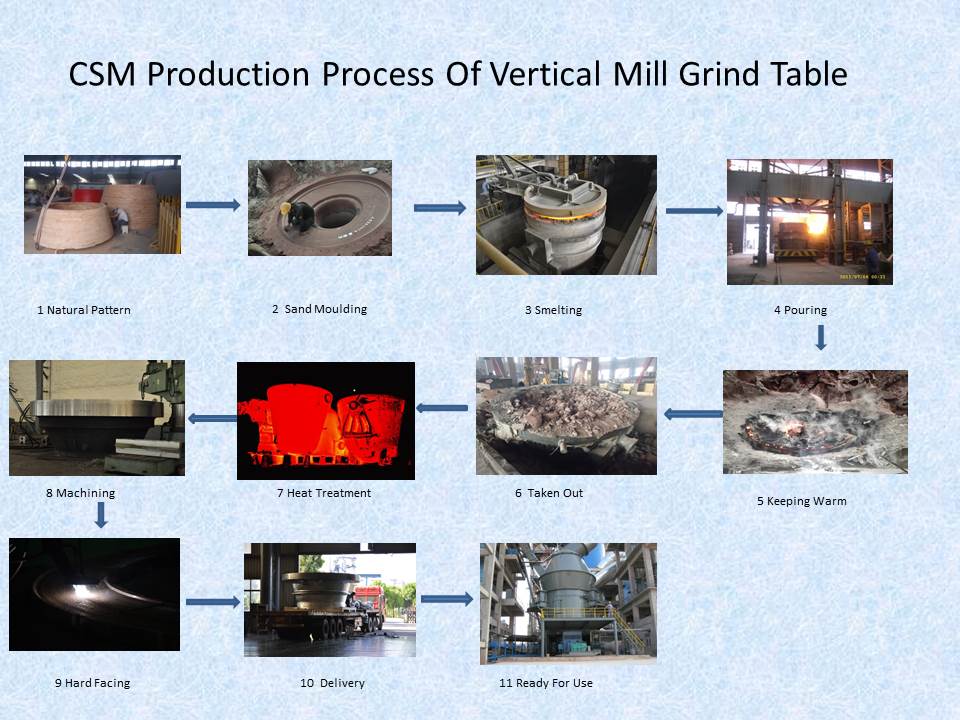

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

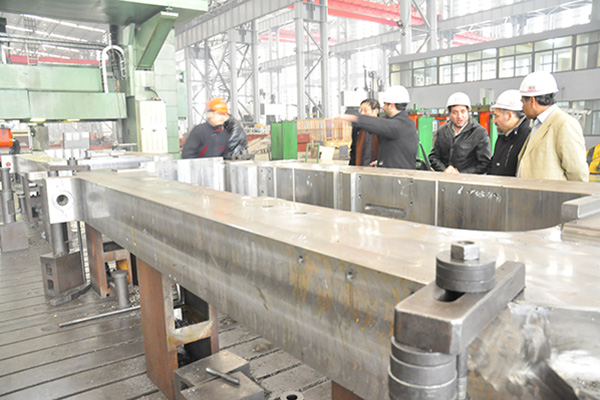

Pictures:

Product detail pictures:

Related Product Guide:

Q & A: Museum of the Future, Denis McNelis, engineering manager, BAM Higgs & Hill – Project News | Lead Ingot Mold

Advanced Copper Foil Announces New Arsenic-Free Copper Foils | Copper Foil Manufacturing Facilities

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Discount wholesale New Foundry Casting Lip Pouring Ladle - Vertical Mill and Spare Parts vertical mill hub – Special Metal, The product will supply to all over the world, such as: New Zealand , Rotterdam , Costa rica , Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.