Big discounting Mill Roll Stand In Packaging Line - Ball Mill End Cover, Stationary Inlet and Outlet – Special Metal Detail:

Ball mill head

Shanghai Special Metal Co., Ltd supplies ball mill head. The materials of mill head are normally selected low carbon steel and low alloy steel. It’s produced by casting, used in ball grinding mill, including the feed end and outlet end, our head/cap for the bellow ball grinding mill.

Ball mill data:

| Model(mmxmm) | Speed of bucket(r/min) | Weight of ball(t) | Size of feed opening(mm) | Production(t/h) | Power(kw) |

| φ900×1800 | 38 | 1.5 | ≤20 | 0.65-2 | 18.5 |

| φ1200×2400 | 32 | 3.8 | ≤25 | 1.5-4.8 | 45 |

| φ1500×5700 | 27 | 15 | ≤25 | 3.5-6 | 132 |

| φ2200×5500 | 21 | 30 | ≤25 | 10-22 | 370 |

| φ2400×10000 | 20.8 | 49 | ≤25 | 22 | 630 |

| φ3000×13000 | 18.2 | 115 | ≤25 | 40-42 |

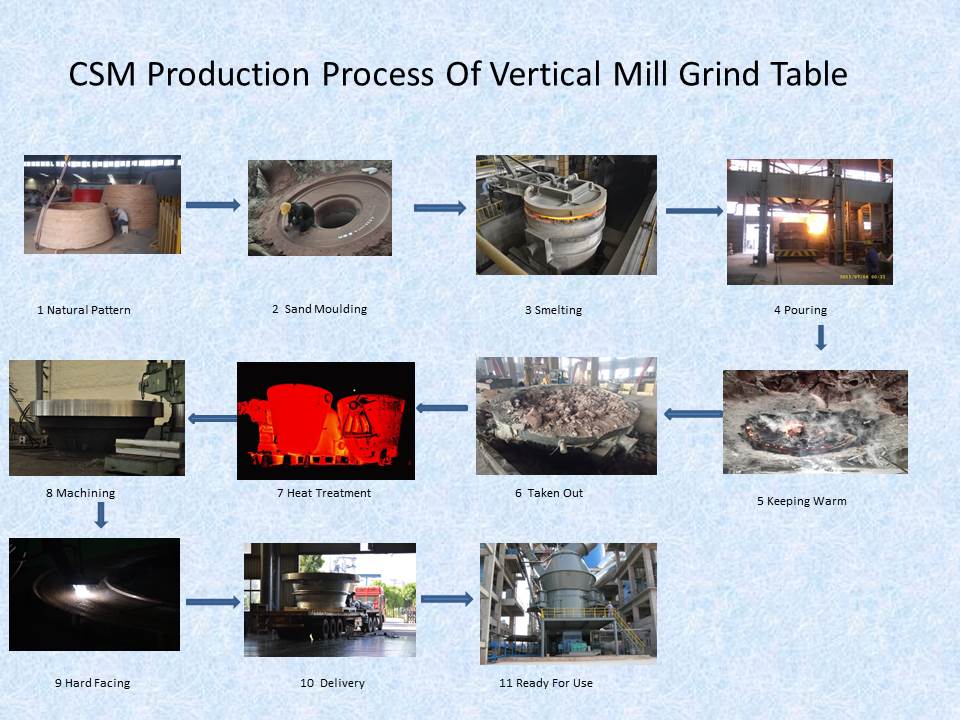

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

Product detail pictures:

Related Product Guide:

Stephen Fry reveals flu jab saved his life | Lead Ingot Mold

Vostok has the space beer, now it needs the space beer bottle | Lead Ingot Mold

In an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our greatest provider and item for Big discounting Mill Roll Stand In Packaging Line - Ball Mill End Cover, Stationary Inlet and Outlet – Special Metal, The product will supply to all over the world, such as: Madras , Moscow , France , Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!