Big Discount Aluminum Titanate Casting Ladle - Rotary kiln tyre – Special Metal Detail:

Rotary kiln tyre

Weight: 5~80T

Applicable devices: rotary kiln type

Application: Cement, Metallurgy, chemical industry, building etc.

Customizable or not: Yes

Product introduction

Tyre is another name for rolling ring, which is the main part of rotary kiln. The function of tyre is to transfer the whole weight (including firebrick, interior device and material) to riding wheel to make barrel stably move round at riding wheel. Therefore, tyre should have excellent strength and wear resistance; meanwhile, it is the part to enhance radial stiffness of barrel, so it should have excellent stiffness

Our main material for the Rotary kiln tyre is similar to followings:

|

Standard Specifications for Cast Steel |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS EN 10083/2-1991 | C45 |

| USA | ASTM A 29/A29M-04 | 1045 |

| Germany | DIN EN 10083-2-2006 | C45/CK45 |

| Japan | JIS G5111 | SCC5 |

| International | ISO 683/1 | C45/C45E4/C45M2 |

|

Standard Specifications for Cast Steel |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS 970-1 | 708 A42 |

| USA | ASTM A 29/A29M-04 | 4140/4142 |

| Germany | DIN EN 10083-1-1996 | 42CrMo4 |

| Japan | JIS G4053-2003 | SCM440 |

| International | ISO 683/1 | 3 |

Advantage

1. High strength, excellent wear resistance

Shanghai Special Metal uses ZG45 and ZG42CrMo to cast rotary kiln tyre to ensure high strength and excellent toughness, which is good for supporting.

2. Adopting double medium quenching process while casting tyre to enhance the flexibility

Shanghai Special Metal adopts advanced double medium quenching process and forges equally each part, which enhance the hardness and toughness to get high wear resistance to adapt all kinds of bad working conditions

3. Type has a simply structure. It is convenient to manufacture and to do routine maintenance

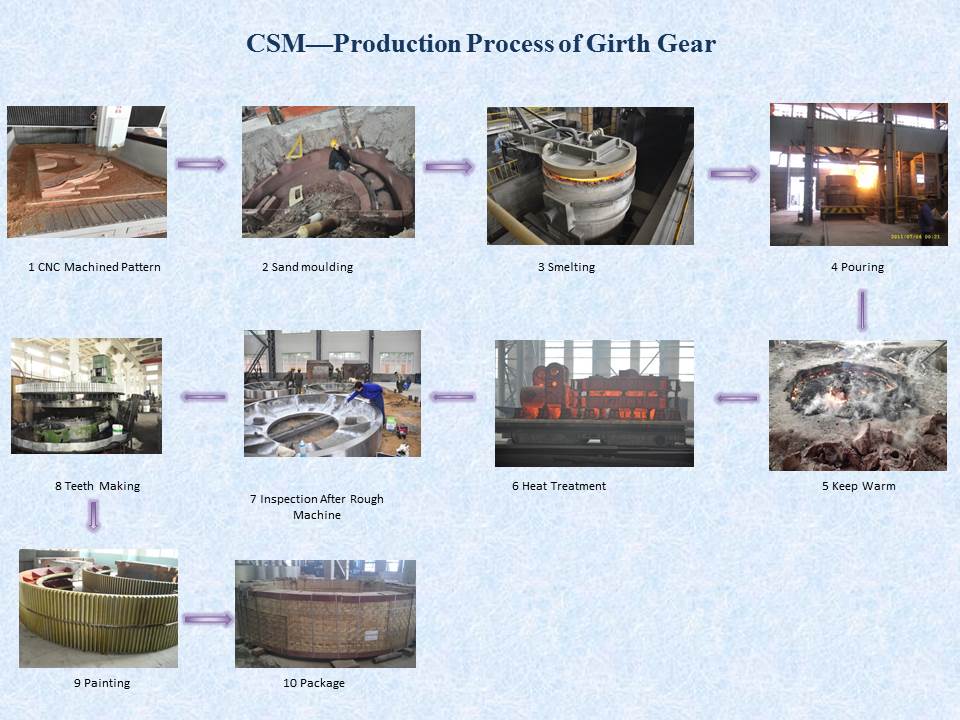

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

• Carry out NDT(Non-destructive Testing) inspection at least at level 2.

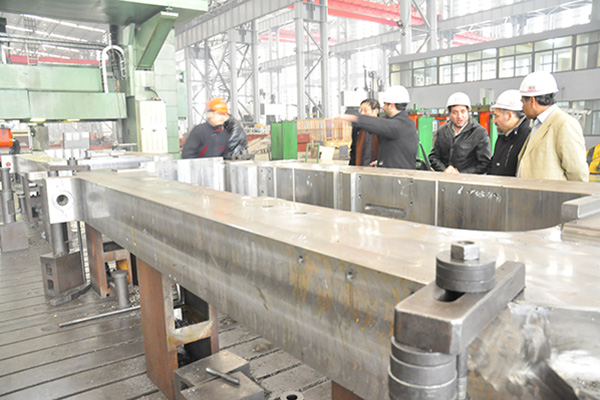

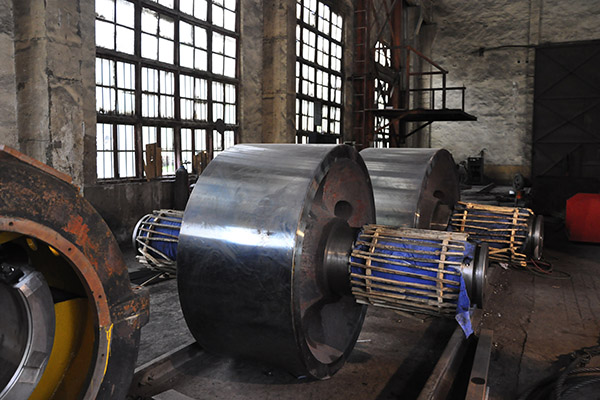

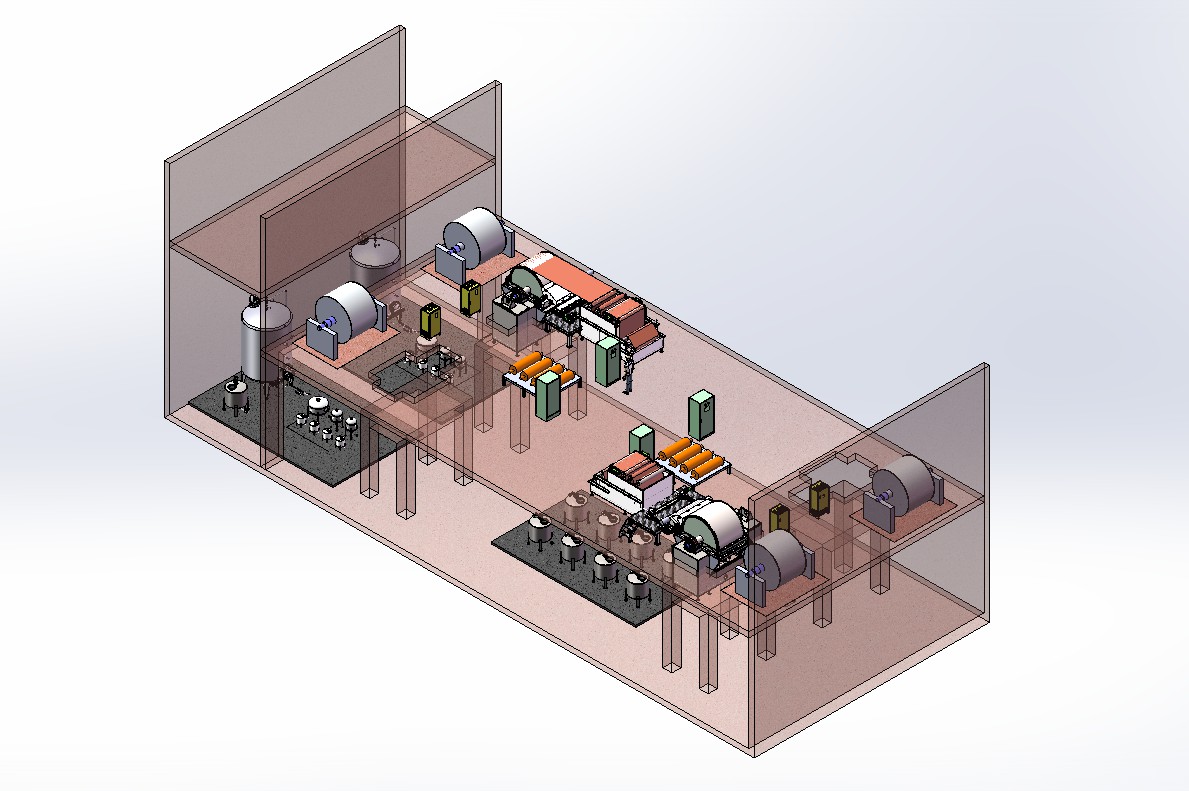

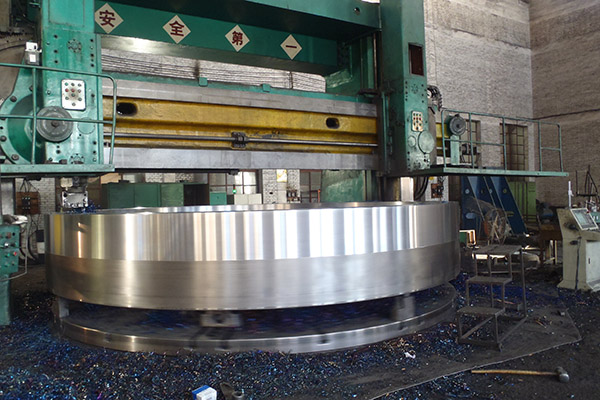

Pictures

Product detail pictures:

Related Product Guide:

Ease of Living Index ranks Navi Mumbai, Greater Mumbai at the top but conclusions of survey are laughable | Slag Pots

Q & A: Museum of the Future, Denis McNelis, engineering manager, BAM Higgs & Hill – Project News | Copper Foil Manufacturing Facilities

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Big Discount Aluminum Titanate Casting Ladle - Rotary kiln tyre – Special Metal, The product will supply to all over the world, such as: Porto , Sheffield , New Delhi , As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.