18 Years Factory Scrap Battery Lead Smelting Cupola Furnace - Riding wheel for rotary kiln – Special Metal Detail:

Riding wheel for rotary kiln

Weight:7~42T

Applicable device: Rotary Kilns

Application: Cement, metallurgy, chemical, construction industries, etc

Customizable: Yes

Product introduction

Our main material for the Riding wheel for rotary kiln is similar to followings:

|

Standard Specifications for Cast Steel ZG55 |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS3100 | A5 |

| USA | AISI/SAE | UNS J05000 |

| Germany | / | / |

| Japan | / | / |

| International | ISO 3755:1991 | 340-550 |

|

Standard Specifications for Cast Steel ZG42CrMo |

||

|

Country |

Standard |

Grade |

| United Kingdom | BS 970-1 | 708A42 |

| USA | ASTM A29/A29M | 4140/4142 |

| Germany | EN10083-1 | 42CrMo4 |

| Japan | JIS G4053-2003 | SCM440 |

| International | ISO 683/1 | 3 |

Advantages:

1. Large load bearing, good continuous operation performance

We CSM riding wheel are made from ZG55 and ZG42CrMo. This kind of material guarantee the quality of riding wheel, and also make riding wheel large loading bearing and good continuous operation performance.

2. Simple structure, convenient to adjust and maintain.

This kind of riding wheel uses rolling bearing wheel sets, and is simple in structure and convenient to maintain.

3. Heat treated through normalizing and tempering, hardness of riding wheel is higher.

We CSM apply normalizing and tempering heat, which makes riding wheel’s outer surface hardness higher than 200HB; guarantee the quality of riding wheel for rotary kiln.

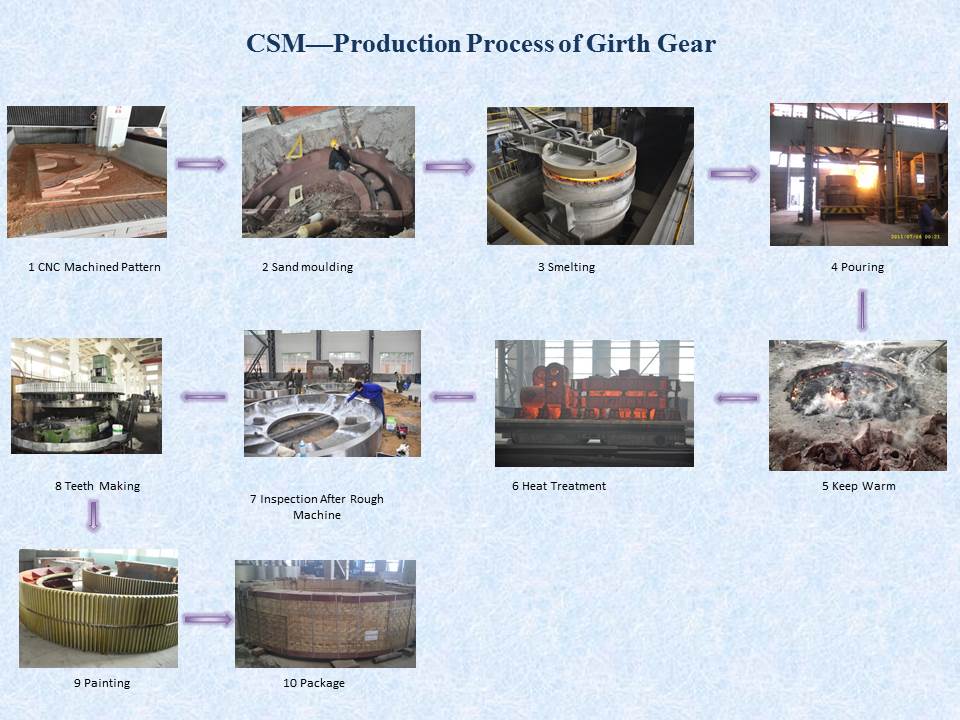

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

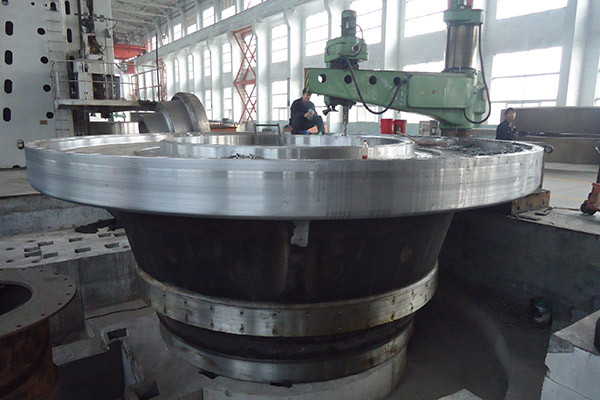

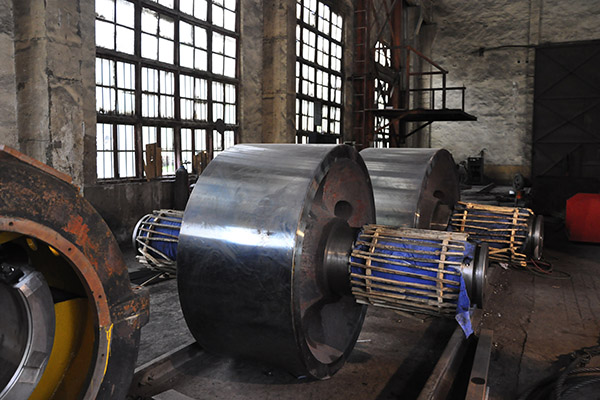

Picture:

Product detail pictures:

Related Product Guide:

High-end Copper Foil(Less than 10 ?m) Market 2018| Global Market Status( 2013-2017) and Forecast(2018-2025) | Single Stage Hammer Crushers

Global Copper Coil for Battery Market Insights 2018-2025: China-Kinwa High Technology, LS, CCP, Furukawa Electric | Copper Foil Manufacturing Facilities

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for 18 Years Factory Scrap Battery Lead Smelting Cupola Furnace - Riding wheel for rotary kiln – Special Metal, The product will supply to all over the world, such as: Mozambique , Kazakhstan , Ethiopia , To work with an excellent items manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.