OEM/ODM Factory Foundry Pouring Ladle - Chucks with or without Hydro-cylinder – Special Metal Detail:

Chocks

Weight: 3~20T

Applicable device: mill parts

Application: Cement, electricity, metallurgy, chemical and others

Customizable: Yes

Introduction

Bearing chock plays an important role of fixing bearing and bearing weight. It is the core part of rolling bearing. Its main function is to support the whole bearing structure.

Bearing chock works under low speed and heavy load for long time. So its reliability is the most important feature. To achieve this feature, it must require good quality of bearing chock.

Our main material for the bearing chock is similar as following

|

Standard Specifications for Cast Steel SCW480 |

||

|

Country |

Standard |

Grade |

| China | GB/T 11352-1989 | ZG20SiMn |

| United Kingdom | / | / |

| USA | AISI/SAE | UNS J02505 |

| Japan | JIS-G5102 | SCW480 |

| Germany | DIN 17182 | GS-20Mn5 |

| International | / | / |

Advantage

1. Fine material, high level of wear resisting

SHANGHAI SPECIAL METAL CO., LTD uses SCW480 to produce bearing chock, to ensure products’ quality. Through the test of practice, bearing chocks produced by SHANGHAI SPECIAL METAL CO., LTD can work well under long-time, heavy load operation with small wear loss.

2. Equipped with monitoring devices, can get operation condition at any time

Below bearing chock, there’s an oil leveler. Operator can view oil level at any time, supplement oil in time, avoid poor lubrication and bearing damage lead from oil lacking.

3. Reasonable structure, good for long-time and stable operation

Removed outside top cover, this design avoids dusts go into bearing box, improves bearing’s working life, and secures its work.

4. Holes of cylinder-oil with the degree of finish Ra 0.02

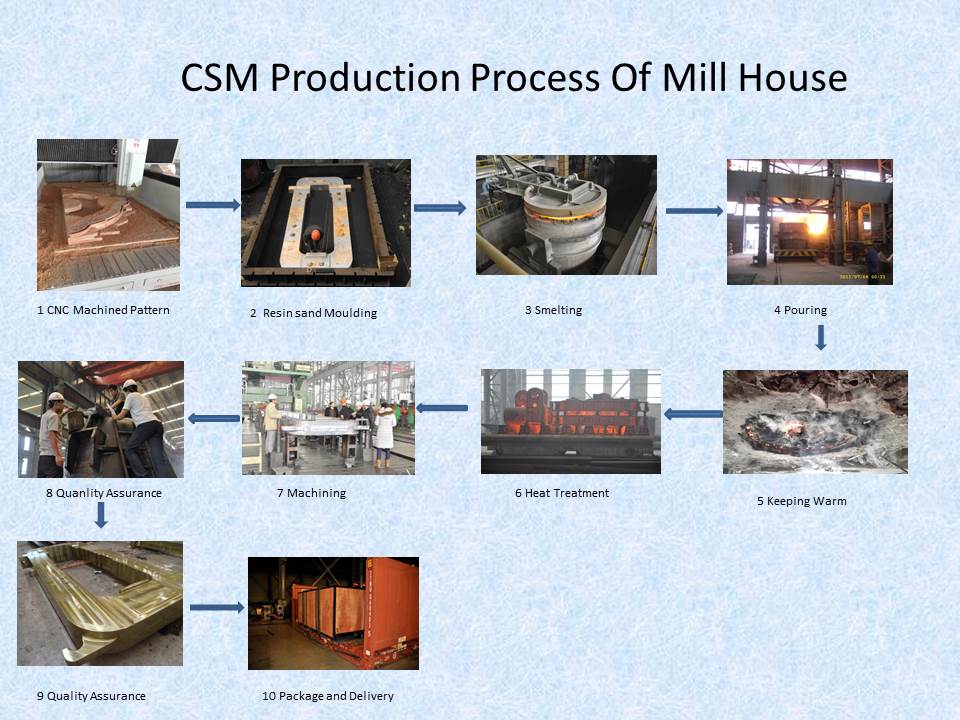

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Pictures:

Product detail pictures:

Related Product Guide:

Volvo L150Gs keep their cool at molten steel mill – Products & Services | Lead Ingot Mold

New Audi A8 to feature more lightweight tech | Slag Pots

Along with the "Client-Oriented" small business philosophy, a rigorous high-quality handle system, highly developed producing machines and a powerful R&D group, we always supply high-quality products and solutions, fantastic services and aggressive costs for OEM/ODM Factory Foundry Pouring Ladle - Chucks with or without Hydro-cylinder – Special Metal, The product will supply to all over the world, such as: Cape Town , panama , Algeria , If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!