Bottom price Aluminum Die Casting Moulding - Mechanical Machine Pump Spares Water Pump Casing – Special Metal Detail:

The pump casing we offer can meet the followings:

1. Tolerance size of the casting shall conform to ISO8026-3 DCTG 13-RMA 6(RMAG H)-GCTG 7-DS

2. Cracks, burnt, sand and slag inclusions are not allowed. On the unhandled surfaces should not be defects reducing the strength, performance and degrade casting presentation. Allowed correction of welding, in which defective cutting may be performed by the manufacturer’s instruction. Locations of these defects in the casting and the butchering size under welding must be registered and entered in the casting documents. After removal of butchering defects, the surface should be grinded and monitored for completeness remove defects by dye penetration

3. Carry out UT of the castings: the end surfaces along the entire length in the area of the flange connector of the pump housing and cover (zone 1) in the area of the suction flange connector (zone2),in the area of the discharge flange connector (zone3), permitted without correcting defects of the equivalent size to 5mm not more than 3pcs.

4. The conformity checking with the chemical composition of the steels should be carried out from the each melt.

The chemical composition of castings:

|

Mass fraction of component % |

||||

|

C |

Mn |

Si |

P | S |

|

No more than |

||||

| 0.22-0.30 | 0.45-0.9 | 0.2-0.52 | 0.05 | 0.05 |

5. The steel mechanical properties: Tensile strength not less 441MPa, elongation Q not less 19%, impact strength not less 392KJ/m2, hardness HB 121-151. The mechanical properties of the steel are necessary to control for each melt. Test results apply to all the castings from this melt, heat-treated in the same mode, record by automatic devices.

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

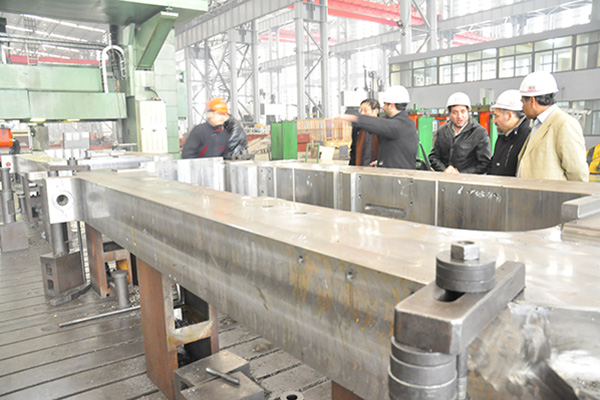

Product detail pictures:

Related Product Guide:

BHP centenary of steel: Timeline, video photos | Slag Pots

Stephen Fry reveals flu jab saved his life | Single Stage Hammer Crushers

Our business sticks for the basic principle of "Quality could be the life with the firm, and track record will be the soul of it" for Bottom price Aluminum Die Casting Moulding - Mechanical Machine Pump Spares Water Pump Casing – Special Metal, The product will supply to all over the world, such as: Johannesburg , Algeria , Serbia , Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!